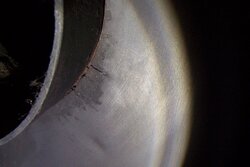

Have had my Fisher Mama Bear since 1978 and have used it as our primary heat source in Western Massachusetts. Because of storms last Fall, we decided to repair our masonry chimney and then got involved in a total rebuild. We had to pull out the stove (had been connect to a stainless liner) and it was then we noticed the outet collar was separating from the collar as it went internal. Can we solder the collar back on to the rest of the collar? We are looking for a mobile welder to do this job and hoping Coaly or others may have some suggestions. Also found some hairline crack in the back about 1/4 inch if that on either side of the collar - these look to be hairline. Could we fix this as well?

About 10 years ago we had a chimney fire and therefore ended up with the stainless liner as the red liner in our chimney was cracked from the fire.

Lastly, the stove going on 33 years old and on examination, I noticed two fire bricks on each side cracked - I think each was the 4th one in from the front. One is a more than cracked - a small triangualr chunk missing.

I have no idea on how to take out and replace the bricks - do masons do this kind of work?

Love our Fisher and hate to retire it as it has been so good to us and odd to say, almost a member of the family. The new EPA stoves do not thrill us at all. Hoping you guys have some good advise for me. My grown kids are angry that we are even considering retiring the stove -they don't even live with us anymore and they are upset. My husband is not physically able to do this work himself any longer so have to find welders etc. to help us. I do have lead on a mobile welder but not sure if he is familiar with this kind of work and the fire bricks stump me -they look jammed in their pretty good and even if I smashed and hammered them out - I would have not clue as to how to reset them.

thanks in advance for advice (or sympathy) whichever it may be!

About 10 years ago we had a chimney fire and therefore ended up with the stainless liner as the red liner in our chimney was cracked from the fire.

Lastly, the stove going on 33 years old and on examination, I noticed two fire bricks on each side cracked - I think each was the 4th one in from the front. One is a more than cracked - a small triangualr chunk missing.

I have no idea on how to take out and replace the bricks - do masons do this kind of work?

Love our Fisher and hate to retire it as it has been so good to us and odd to say, almost a member of the family. The new EPA stoves do not thrill us at all. Hoping you guys have some good advise for me. My grown kids are angry that we are even considering retiring the stove -they don't even live with us anymore and they are upset. My husband is not physically able to do this work himself any longer so have to find welders etc. to help us. I do have lead on a mobile welder but not sure if he is familiar with this kind of work and the fire bricks stump me -they look jammed in their pretty good and even if I smashed and hammered them out - I would have not clue as to how to reset them.

thanks in advance for advice (or sympathy) whichever it may be!