I continue to learn as I use my wood fired boiler as there are so many things to observe. I have previously posted information on this forum that I would like to comment on further.

Stack temperatures. I previously stated it was in the region of 400 C. (750 F) It does exceed this figure on occasions but of late it has been running at about 240 C (464 F) The stack temperature can vary quite markedly. However, I am happy to see it on the high side rather than on the cool side.

Fly ash in the heat exchanger I previously stated I was having a problem with fly ash carrying through the heat exchanger. This problem only occurred when the inlet air filter became blocked and the fire was not burning with it's full intensity. After replacing the filter the problem with the fly ash is no longer present. I can only presume that with a hot fire the ash is almost fully consumed. I have taken note of Hobbyheater's suggestion to remove the ash from the burn chamber on a regular basis which doesn't take long using a tin on the end of a stick followed by vacuum cleaning.

I finally got around to encasing the burn chamber with a mixture of vermiculite and portland cement. This has made a significant difference to the efficiency of the boiler as heat is retained in the burn chamber for a much longer period of time which makes starting a new burn much easier.

Comments about wood to be burnt. I do not buy timber to burn and scrounge around to find anything I can burn. In this regard timber that others leave behind such as tree stumps and gnarled remnants burn fine in my boiler. Whilst sticks burn with the greatest intensity I have found I can burn very large single pieces of wood if they are loaded when the fire is at fully established and running hot.

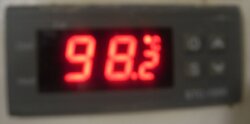

Temperature of water. For efficient heating with panel radiators I have found the water needs to be at least 70C (160 F) or hotter. Yesterday I heated the water to 98 C and the heating was magnificent. However, I consider that degree of heat too high for safety.

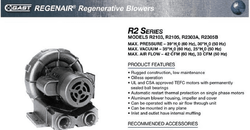

The new air filter

Rough pieces of timber that I can burn

The burn chamber encased with insulating cement

Too hot for safety!

Stack temperatures. I previously stated it was in the region of 400 C. (750 F) It does exceed this figure on occasions but of late it has been running at about 240 C (464 F) The stack temperature can vary quite markedly. However, I am happy to see it on the high side rather than on the cool side.

Fly ash in the heat exchanger I previously stated I was having a problem with fly ash carrying through the heat exchanger. This problem only occurred when the inlet air filter became blocked and the fire was not burning with it's full intensity. After replacing the filter the problem with the fly ash is no longer present. I can only presume that with a hot fire the ash is almost fully consumed. I have taken note of Hobbyheater's suggestion to remove the ash from the burn chamber on a regular basis which doesn't take long using a tin on the end of a stick followed by vacuum cleaning.

I finally got around to encasing the burn chamber with a mixture of vermiculite and portland cement. This has made a significant difference to the efficiency of the boiler as heat is retained in the burn chamber for a much longer period of time which makes starting a new burn much easier.

Comments about wood to be burnt. I do not buy timber to burn and scrounge around to find anything I can burn. In this regard timber that others leave behind such as tree stumps and gnarled remnants burn fine in my boiler. Whilst sticks burn with the greatest intensity I have found I can burn very large single pieces of wood if they are loaded when the fire is at fully established and running hot.

Temperature of water. For efficient heating with panel radiators I have found the water needs to be at least 70C (160 F) or hotter. Yesterday I heated the water to 98 C and the heating was magnificent. However, I consider that degree of heat too high for safety.

The new air filter

Rough pieces of timber that I can burn

The burn chamber encased with insulating cement

Too hot for safety!