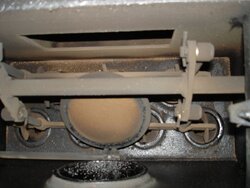

As some may have read my saga.... I am not able to get over 275F at the flue outlet of the boiler. This is measured with the electronic stack probe that can be displayed on the digital readout, as well as my cheapo magnetic burn indicator on the flue neck of the boiler. I feel this is way too cold, and thinking my wood is too wet to achieve full gasification. I am going to break down and buy one of those dumb kiln-dried shrink wrapped wood stacks @Lowes and make one last attempt to see what the temps will do with really dry wood. I may remove the turbulators and try also. I've burned several loads and seem to be having gasification as the refractory is clean and makes a good rumble, however I'm getting uncomfortable with the amount of shiney tar-like creosote on all the steel in the lower chamber and migrating to the firetubes. This is my first expierence with a gasser and also this boiler which by comparison uses much less wood, but is lack-luster in tar production. Post some stack temps y'all get with a normal fire and how long it takes to get there. I can get to 250F in about 10 min from a cold start, but no higher unless of course I open the bypass. Help me feel better about this large cash outlay wood burner upgrade, the old NY-WC 130 had much less of a learning curve when it was in place of the Attack, I controlled the draft to maintain 350-400 stack and never had ANY chimney buildup, just let the heat (and smoke billowing) right up the chimney and all was good!

TS

TS

. If I have good gassification then my temp is around 400. If I lose gassification because of a blow through my coal bed the temp will quickly rise to 550-600

. If I have good gassification then my temp is around 400. If I lose gassification because of a blow through my coal bed the temp will quickly rise to 550-600  I get a little to talkative sometimes.

I get a little to talkative sometimes.