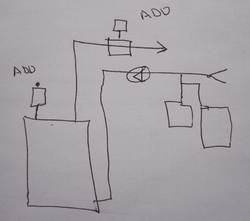

This systom i am helping a friend on has NO air release purge valves anywhere.Still can here air gurgle in the pipes but is better now since i tried valve. Couple on the top baseboards is all. I thought in stead of taking everything apart to put a air valve in why not use a saddle valve,?? Put on,poke hole, let air out and cap off. I did put one on it seems to work good.good to 1 1/4 pipe.

Anything I am missing here?

Anything I am missing here?

You need to move fluid at least 2 feet per second to push air along, and get it back to a point where a vent can function. The old gravity systems were an engineered system, much different than todays small piped systems. Small diameter piping needs flow velocity, imparted by the circ pump, to overcome the piping resistance.

You need to move fluid at least 2 feet per second to push air along, and get it back to a point where a vent can function. The old gravity systems were an engineered system, much different than todays small piped systems. Small diameter piping needs flow velocity, imparted by the circ pump, to overcome the piping resistance.