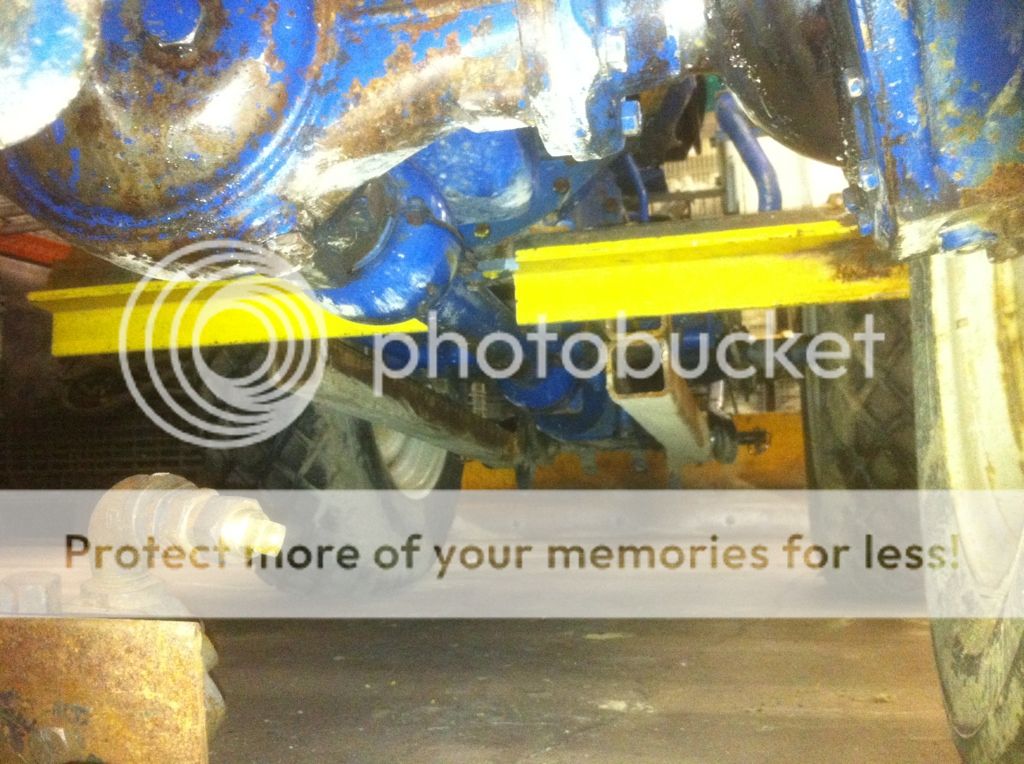

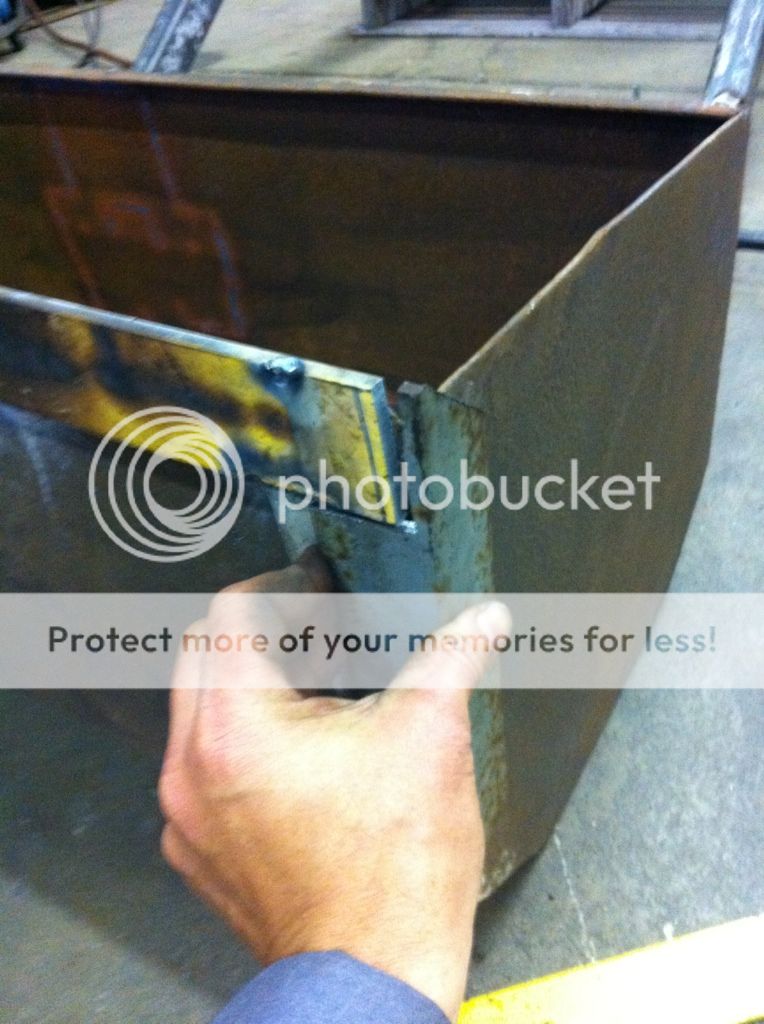

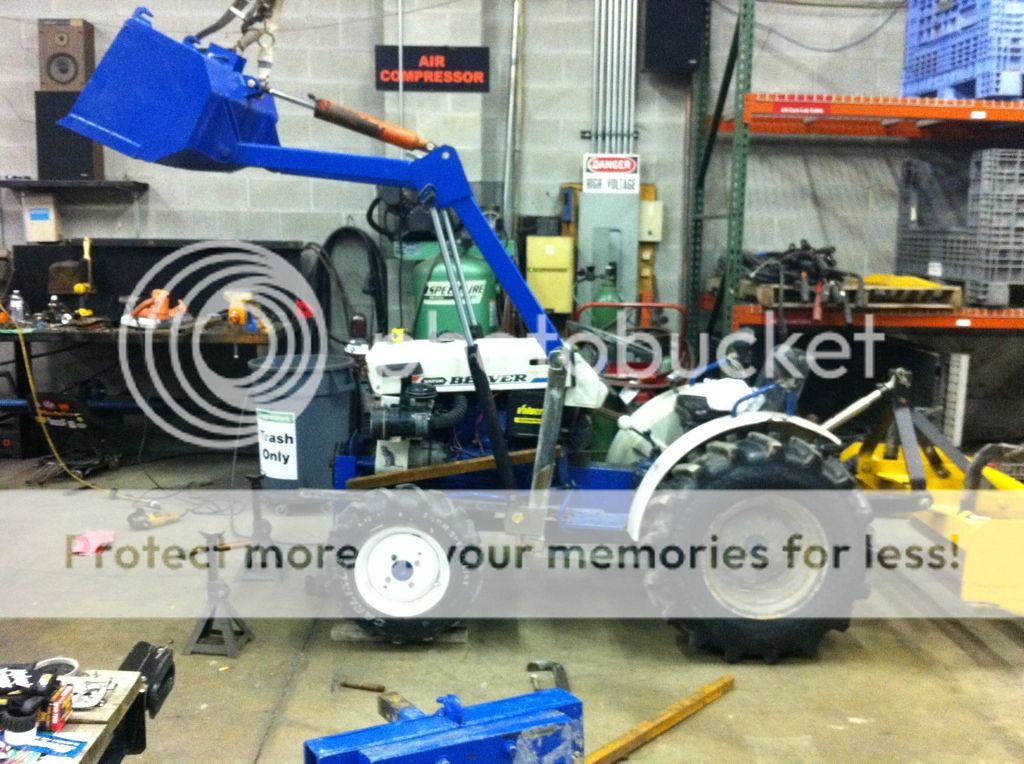

I thought I would post up what i've been up too. i bought my first house last fall and still getting the property in order. I don't travel as much as I used to, but I did spend the first 6 months of this year out of town. I had a ton of tractor work to do on my land to resolve drainage issues... Traded a junk mustang roller for this running tractor. I Did some wheelin' and dealin' over the last couple weeks and ended up with this loader setup off of an old economy tractor. I believe it was home made at some point in time... It was a complete setup with hydraulics, hyd tank, pump, cylinders, spool valves and hoses. The bucket is 42" wide and seems like a perfect match for the little beaver.

even got a set of hayforks with it. I'll eventually make a grapple for this so I can use it to move brush and trees around.

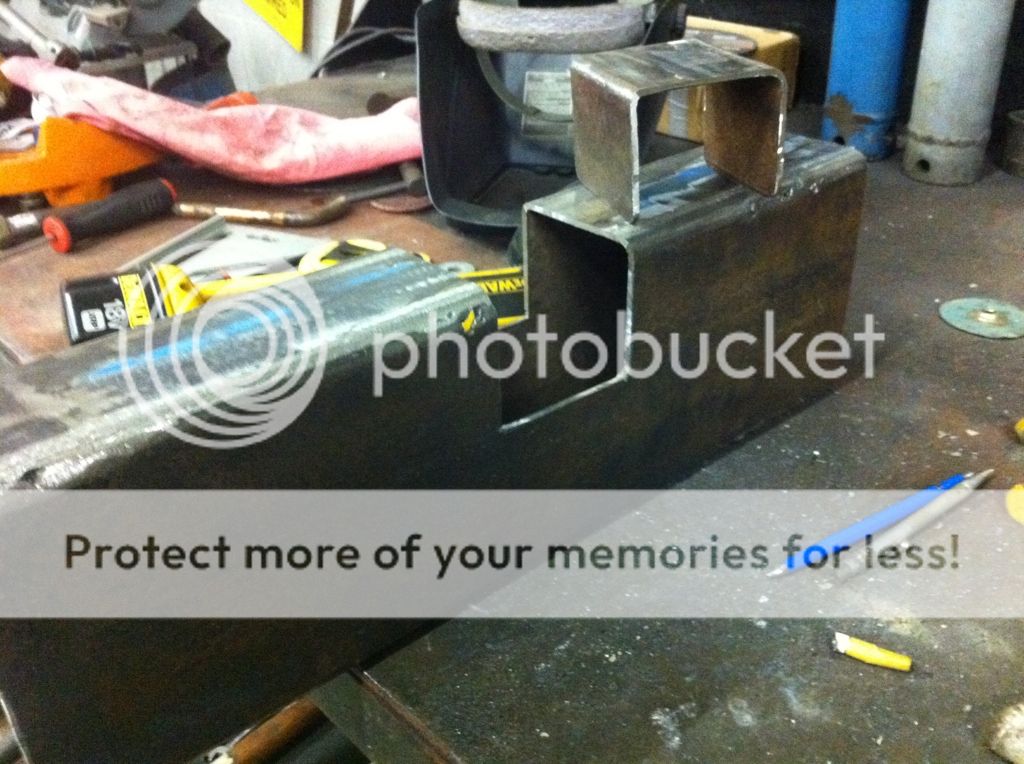

instead of trying to modify what was there....I just started over....

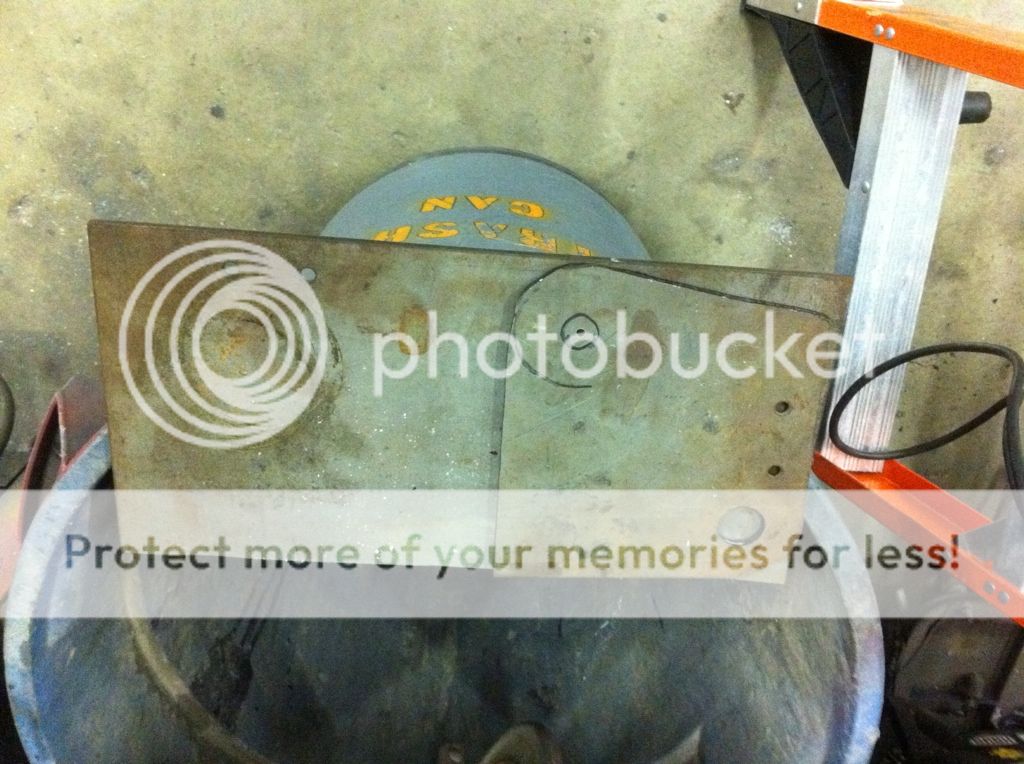

I did resuse the sleeved bushings off of the old loader frame.... Here are my sophisticated set of Freakin' plans...lol

here is the start of the mockup....I used some 2x4's to get the propper angles...(no pics, sorry) easier and cheaper trial and error with free 2x4's...

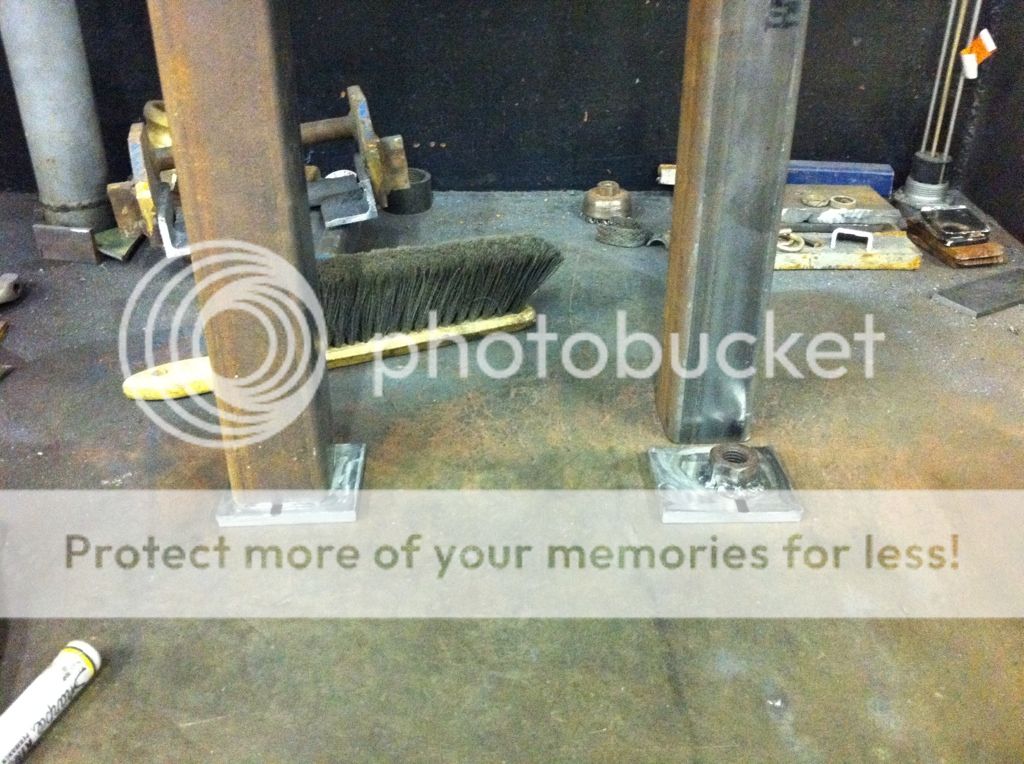

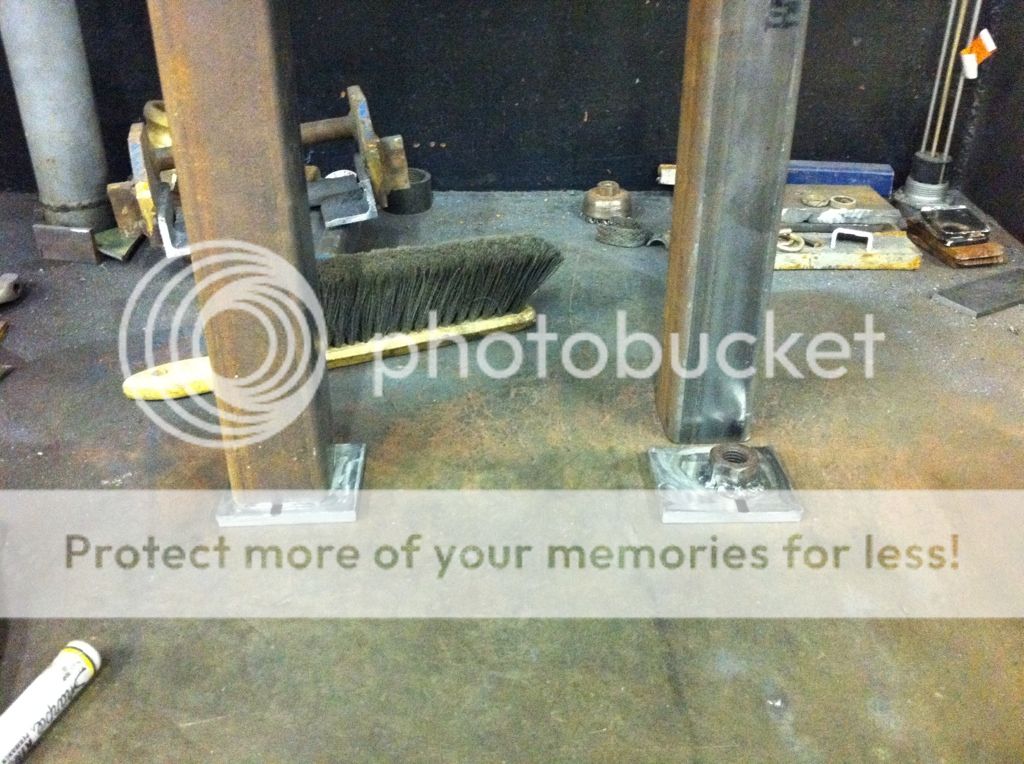

For the upright posts, I used 2 1/2" box tube, 1/4" wall. I used 3/8 plate and drilled 7/8" holes in the pivot plates and welded them to the tubes. I'll eventually box in the backside and add some more reinforcement to them.

For the bottom of the upright tube, I used a 4"L x 3"W 1/2" plate. I drilled a 1" hole in the plate and then welded a nut on the topside of the plate. The nut will sit inside the box tube upright. I did this incase I want to ever remove the setup.

even got a set of hayforks with it. I'll eventually make a grapple for this so I can use it to move brush and trees around.

instead of trying to modify what was there....I just started over....

I did resuse the sleeved bushings off of the old loader frame.... Here are my sophisticated set of Freakin' plans...lol

here is the start of the mockup....I used some 2x4's to get the propper angles...(no pics, sorry) easier and cheaper trial and error with free 2x4's...

For the upright posts, I used 2 1/2" box tube, 1/4" wall. I used 3/8 plate and drilled 7/8" holes in the pivot plates and welded them to the tubes. I'll eventually box in the backside and add some more reinforcement to them.

For the bottom of the upright tube, I used a 4"L x 3"W 1/2" plate. I drilled a 1" hole in the plate and then welded a nut on the topside of the plate. The nut will sit inside the box tube upright. I did this incase I want to ever remove the setup.