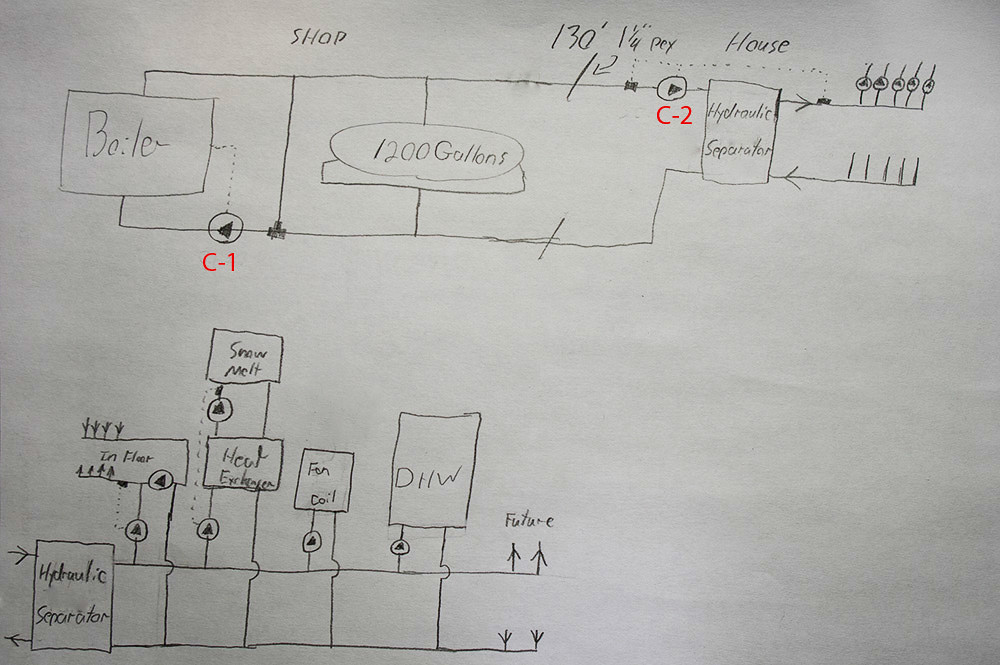

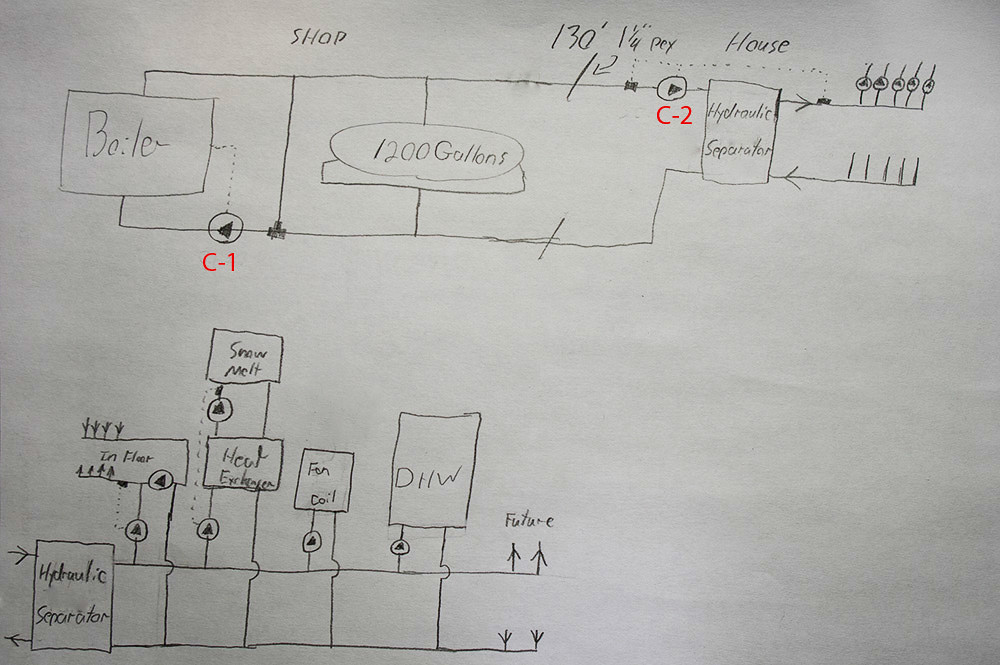

Hello all. I'm helping a friend with a boiler install and have some questions. This is a rough idea of what I have in mind for the plumbing layout. I'm looking for thoughts, ideas and improvements. I left out all the fittings (exp tank included) and just drew in the circulators, so not to worry if looks too bare.

The boiler is a gasser and will run flat out and have return protection. Any excess heat will go to storage. That part I'm fine with. On the house side space is at a premium. The idea is to have the 130' supply/return underground pex go to a hydraulic separator. C-2 will be a Taco delta T circ set to come on full for 30 sec then maintain a deltaT of 5* across the hydraulic separator when ever there's a call for heat. To me this will keep C-2 almost matching the flow for the loads house side.

The main heat for the house is the hot air coil. The whole idea of this set up, is from a cold start the boiler can heat up and provide maxim heat and flow to the house if the storage is at say 80*F

All comments are welcome

Thank you.

PS looking at this now should C-2 be on the return side of the hydraulic separator? pushing back towards the boiler/storage.

The boiler is a gasser and will run flat out and have return protection. Any excess heat will go to storage. That part I'm fine with. On the house side space is at a premium. The idea is to have the 130' supply/return underground pex go to a hydraulic separator. C-2 will be a Taco delta T circ set to come on full for 30 sec then maintain a deltaT of 5* across the hydraulic separator when ever there's a call for heat. To me this will keep C-2 almost matching the flow for the loads house side.

The main heat for the house is the hot air coil. The whole idea of this set up, is from a cold start the boiler can heat up and provide maxim heat and flow to the house if the storage is at say 80*F

All comments are welcome

Thank you.

PS looking at this now should C-2 be on the return side of the hydraulic separator? pushing back towards the boiler/storage.