- Jan 22, 2013

- 19

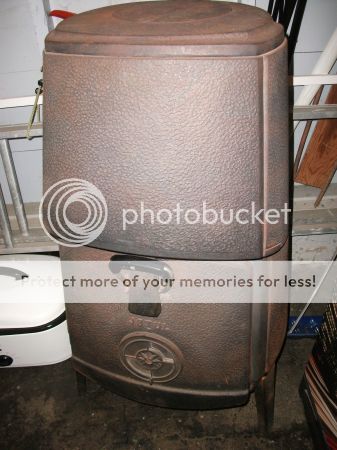

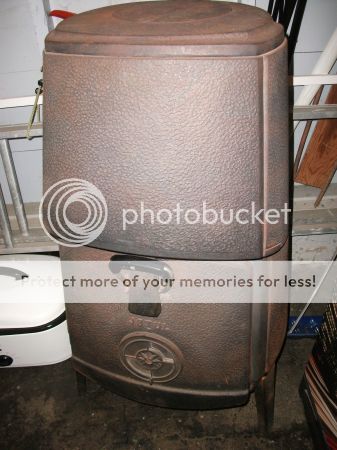

I am considering a Jotul Combi-Fire 4 advertised locally, but so far have only a photo of the outside which appears to have surface rust. The seller says some of the fire bricks are broken and it needs a new door seal. He was asking $350 but says "I would be willing to drop the price if the bricks are an issue."

Of course broken fire bricks ARE an issue; is there a source for these fluted bricks or a reasonable substitute? And what might one be looking at cost wise to replace firebricks and door seal?

Of course broken fire bricks ARE an issue; is there a source for these fluted bricks or a reasonable substitute? And what might one be looking at cost wise to replace firebricks and door seal?