Some know of the reliability concerns i have previously raised regarding the Merkle motors and the testing i have done on the Gleason Avery. For those that dont, the thread is here:

https://www.hearth.com/talk/threads/englander-auger-motor-failure-and-replacement.30454/

Recently i tried to order a GA motor in CCW form as i had done previously. The GA rep told me that as a result of an arrangement with Englander they could not sell me a CCW motor and i would have to buy one directly from Englander. I hung up and several days later order a GA CW motor anyway.

I did give Englander a chance to clarify in the thread above. Through an arragement i had to pay Englander $130 for a motor that retails for $80 ?????????????????

I received my GA motor and have converted it from CW to CCW through the following steps:

Remove bearing cover screws.

Remove bearing cover and armature.

Remove stack screws.

Remove stack and flip it over.

Start but do not tighten stack screws.

Insert armature and bearing cover and start screws.

Make sure everything is lined up perfectly and flush before tightening screws.

See photos below. Sorry that i didnt include a photo of the stack out.

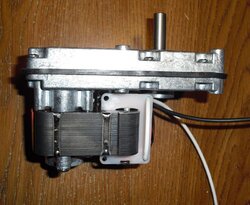

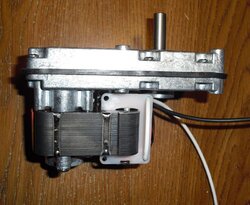

In the first photo you can see wire leads are towards outer edge of motor, in the last you can see leads are pointing opposite.

As i did in my previous thread i will check in so often to confirm the motor is running.

https://www.hearth.com/talk/threads/englander-auger-motor-failure-and-replacement.30454/

Recently i tried to order a GA motor in CCW form as i had done previously. The GA rep told me that as a result of an arrangement with Englander they could not sell me a CCW motor and i would have to buy one directly from Englander. I hung up and several days later order a GA CW motor anyway.

I did give Englander a chance to clarify in the thread above. Through an arragement i had to pay Englander $130 for a motor that retails for $80 ?????????????????

I received my GA motor and have converted it from CW to CCW through the following steps:

Remove bearing cover screws.

Remove bearing cover and armature.

Remove stack screws.

Remove stack and flip it over.

Start but do not tighten stack screws.

Insert armature and bearing cover and start screws.

Make sure everything is lined up perfectly and flush before tightening screws.

See photos below. Sorry that i didnt include a photo of the stack out.

In the first photo you can see wire leads are towards outer edge of motor, in the last you can see leads are pointing opposite.

As i did in my previous thread i will check in so often to confirm the motor is running.