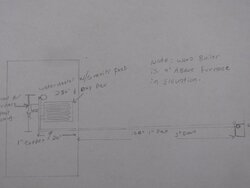

I have a Bell & Gossett PL36 pump. I have a total of 360' of 1" pipe from the boiler outside to the furnace and through the DHW. I already have 240' of 1/2" Pex to the basement floor and stapled between the floor joists. I was wondering if this is too much for the pump. I ask cause I have no idea how to measure head pressure and whatever needs to be figured. I also can't find figures that I could understand. Thanks in advance. The reason I ask is cause I'd like to add just a little bit more cause the ceramic tile floor is so cold. Thanks in advance.

how many feet of pipe am I allowed with my pump?

- Thread starter ihookem

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.