I will be having a new wood stove installed professionally in a couple days and have a question. The stove will be installed in a finished walkout basement, which will require the pipe to travel horizontally thru a 2x6 framed wall before going up thru the roof. Normally, one would just center the thimble between the studs-easy. But, I want the stove centered between two large windows that are 70 inches apart. A stud runs exactly in the center. I don't want to off set the stove as my tile is set and centered between the windows, and moving it over 8 inches wouldn't look right.

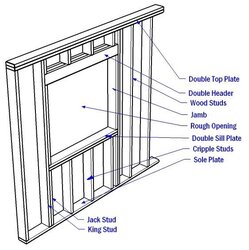

It is a load bearing wall, and I'm not afraid of the 2x6's on either side holding the weight, but a little concerned about the double top plate spanning 32 inches. To avoid ripping out the drywall to the floor, can you just cut the stud to get clearance for thimble, cut drywall to midpoint of studs on each side, screw in a horz 2x6 to cut stud, then screw short 2x6's to support horz one on the studs the drywall was removed to?

I'm sure the intallers don't plan on doing this. They would probably try and center it between studs and go from there. I just want to have the material available for them to do it if it is feasable, and keep the hourly charge to a minimum. I have tried several searches to no avail. Hoping someone out there has some suggestions or a link to another thread.

It is a load bearing wall, and I'm not afraid of the 2x6's on either side holding the weight, but a little concerned about the double top plate spanning 32 inches. To avoid ripping out the drywall to the floor, can you just cut the stud to get clearance for thimble, cut drywall to midpoint of studs on each side, screw in a horz 2x6 to cut stud, then screw short 2x6's to support horz one on the studs the drywall was removed to?

I'm sure the intallers don't plan on doing this. They would probably try and center it between studs and go from there. I just want to have the material available for them to do it if it is feasable, and keep the hourly charge to a minimum. I have tried several searches to no avail. Hoping someone out there has some suggestions or a link to another thread.