I think inexperienced operator proofing a gasification boiler system can be very simple. It requires sufficient storage to make sure 1) the boiler never idles and 2) the boiler never experiences overheat and shuts down or boils over, plus 3) having dry wood of the appropriate split size. Assumed, of course, is that the system is properly designed, including water flow sufficient to handle boiler output.

The Garn comes close to this with its relatively large storage tank, as it does not idle, unless it experiences low water shutdown, but it can be overheated through loading when the tank and demand cannot accept the wood load output. Overheating results in boiling off excessive btu's.

Deep Portage has come closer than I have even seen to inexperienced operator proofing a gasification boiler system. It operates both a Garn WHS 3200 and a Wood Gun E500, together with a 4000 gal storage tank, each boiler having real world output in the range of 500,000 btuH, to heat a 56,000 sq ft facility.

While some staff is experienced, most staff is not, and instructions for staff operation are as simple as A) check to see if wood load has mostly burned out, and if it has ... B) check one digital temperature gauge to see if it is less than 160F; C) if less than 160F, either or both boilers may be loaded with 10-12 splits of wood (this amount weighs about 100 lbs); D) with this wood load the storage (4000 gal + Garn 3200 gal), even if no demand, will accept the full output of both boilers without overheating and without any Wood Gun idling; E) if the digital temperature gauge is 160F or above, do not load either boiler. DP has never experienced a system overheat or Wood Gun idling under this operating procedure.

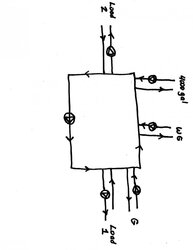

The DP system is primary/secondary piping. The Garn is piped to the primary via a plate hx. The Wood Gun is directly piped to the primary, with return water protection. In addition to two large loads on the primary, a 4000 gal storage tank is piped to the primary as a third load. This storage tank has a sensor at the 4000 gal tank midpoint which outputs to the digital temperature gauge mentioned above. If the Garn alone is operating, its output supplies the primary to meet system demand, if any, and to charge its internal 3200 gal tank plus the 4000 gal storage tank. If both the Garn and the Wood Gun are operating, same result, but if the Garn water temperature is less than the primary loop/storage tank temperature, then the plate hx operates in reverse to heat the Garn, along with Garn output, from the primary loop. If only the Wood Gun is operating, then its output supplies the primary to meet system demand, if any, and to charge both the 4000 gal storage tank and the Garn 3200 gal storage tank.

Inexperienced operators are not responsible for any cleaning or maintenance on these boilers. The inexperienced operators only "load, lock and fire."

=====

It also is possible to come close to inexperienced operator proofing a gasification boiler with storage by using weighed wood burns, but weighing wood would need to be made easy for the operator. The operating procedure would be: A) check to see if wood load has mostly burned out, and if it has ... B) read one digital temperature gauge; C) look at a prepared chart to see how many pounds of wood should be loaded in the boiler based on the gauge temperature reading; D) weigh wood as shown by the chart and load the boiler.

For my system with 1000 gal of storage, I also use a sensor and digital temperature gauge which reads tank temperature at the midpoint. I have a chart with tells me how many pounds of wood to load based on that temperature. I prepared the chart based on 190F ending tank temperature and no system demand. With a 1000 gal tank, and at my boiler efficiency, I know that I need 1.7 lbs of wood to raise the tank temperature 1F. If the temperature gauge reads 130F (desired tank end point temperature = 190F), I simply weigh out and burn 102 lbs of wood.

I built a simple hanging platform with a digital luggage scale for my wood weighing. Look at *bay and you will find these scales for less than $10.

The Garn comes close to this with its relatively large storage tank, as it does not idle, unless it experiences low water shutdown, but it can be overheated through loading when the tank and demand cannot accept the wood load output. Overheating results in boiling off excessive btu's.

Deep Portage has come closer than I have even seen to inexperienced operator proofing a gasification boiler system. It operates both a Garn WHS 3200 and a Wood Gun E500, together with a 4000 gal storage tank, each boiler having real world output in the range of 500,000 btuH, to heat a 56,000 sq ft facility.

While some staff is experienced, most staff is not, and instructions for staff operation are as simple as A) check to see if wood load has mostly burned out, and if it has ... B) check one digital temperature gauge to see if it is less than 160F; C) if less than 160F, either or both boilers may be loaded with 10-12 splits of wood (this amount weighs about 100 lbs); D) with this wood load the storage (4000 gal + Garn 3200 gal), even if no demand, will accept the full output of both boilers without overheating and without any Wood Gun idling; E) if the digital temperature gauge is 160F or above, do not load either boiler. DP has never experienced a system overheat or Wood Gun idling under this operating procedure.

The DP system is primary/secondary piping. The Garn is piped to the primary via a plate hx. The Wood Gun is directly piped to the primary, with return water protection. In addition to two large loads on the primary, a 4000 gal storage tank is piped to the primary as a third load. This storage tank has a sensor at the 4000 gal tank midpoint which outputs to the digital temperature gauge mentioned above. If the Garn alone is operating, its output supplies the primary to meet system demand, if any, and to charge its internal 3200 gal tank plus the 4000 gal storage tank. If both the Garn and the Wood Gun are operating, same result, but if the Garn water temperature is less than the primary loop/storage tank temperature, then the plate hx operates in reverse to heat the Garn, along with Garn output, from the primary loop. If only the Wood Gun is operating, then its output supplies the primary to meet system demand, if any, and to charge both the 4000 gal storage tank and the Garn 3200 gal storage tank.

Inexperienced operators are not responsible for any cleaning or maintenance on these boilers. The inexperienced operators only "load, lock and fire."

=====

It also is possible to come close to inexperienced operator proofing a gasification boiler with storage by using weighed wood burns, but weighing wood would need to be made easy for the operator. The operating procedure would be: A) check to see if wood load has mostly burned out, and if it has ... B) read one digital temperature gauge; C) look at a prepared chart to see how many pounds of wood should be loaded in the boiler based on the gauge temperature reading; D) weigh wood as shown by the chart and load the boiler.

For my system with 1000 gal of storage, I also use a sensor and digital temperature gauge which reads tank temperature at the midpoint. I have a chart with tells me how many pounds of wood to load based on that temperature. I prepared the chart based on 190F ending tank temperature and no system demand. With a 1000 gal tank, and at my boiler efficiency, I know that I need 1.7 lbs of wood to raise the tank temperature 1F. If the temperature gauge reads 130F (desired tank end point temperature = 190F), I simply weigh out and burn 102 lbs of wood.

I built a simple hanging platform with a digital luggage scale for my wood weighing. Look at *bay and you will find these scales for less than $10.

)

) =9.2

=9.2