Hogwildz

Minister of Fire

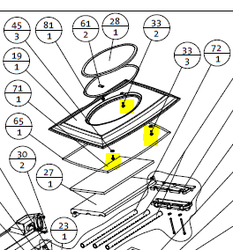

Make sure the baffle board & blanket are pushed all the way back against the rear of the stove.

The baffle should be a ceramic board that lays on top of the burn tubes. The burn tubes are the tubes with the holes, and the insulation lays on top of the ceramic baffle board. Make sure of the following:

As BG said, make sure no debris from cleaning fell onto the top of the insulation &/or baffle board, and are now blocking the stove flue outlet.

Make sure the baffle board & the insulation are snug against the back of the firebox inside.

Is this thing stubbed in vertically, or horizontally? Make sure where it stubs in is not blocked or partially blocked.

Just out of curiosity, how much ash is in the bottom of the stove? Make sure it is not deep and blocking any air port(s) or anything like that. Usually just inside the front of the stove inside at the bottom under the door. Not sure about your brand or model,but something to check if it does have these.

The baffle should be a ceramic board that lays on top of the burn tubes. The burn tubes are the tubes with the holes, and the insulation lays on top of the ceramic baffle board. Make sure of the following:

As BG said, make sure no debris from cleaning fell onto the top of the insulation &/or baffle board, and are now blocking the stove flue outlet.

Make sure the baffle board & the insulation are snug against the back of the firebox inside.

Is this thing stubbed in vertically, or horizontally? Make sure where it stubs in is not blocked or partially blocked.

Just out of curiosity, how much ash is in the bottom of the stove? Make sure it is not deep and blocking any air port(s) or anything like that. Usually just inside the front of the stove inside at the bottom under the door. Not sure about your brand or model,but something to check if it does have these.