Since it's been relatively warm here in southern Missouri and I have a 1000 gallons of storage I haven't had to fire my Biomass 60 for a couple of days, so last night I loaded and fired up my Biomass 60. Just as things started going real good the Biomass suddenly went completely dead...including the controller display...everything. Luckily I have my circ pump wired with a UPS to dump into storage in the event of a power outage so I was able to at least power the pump till the boiler cooled down.

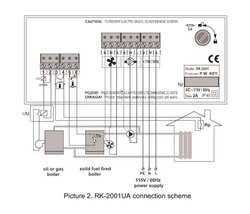

After a bit of troubleshooting I found that the fuse on the RK-2001UA controller had blown. When I replaced the fuse and tried to turn the furnace on, the display briefly flashed on and the fuse immediately blew again. I then disabled the pump and draft fan. This time the firebox fan came on, the controller lit up and stayed on and seemed to operate correctly, including all the functions on the controller. I then plugged in the draft fan and the fuse immediately blew again. After going to town to purchase more of the rather uncommon GMA glass fuses, I tried it again, this time with the firebox blower and the circ pump wired in, and only the draft fan disabled. Again everything seemed to work until I again applied the draft fan...BAM!...fuse blew again!

The draft fan itself works just fine when I apply line voltage to it directly. I don't have a lot of electrical knowledge, but it seems odd to me that this fuse, being just a 2A fuse, is blown by the current draw of the draft fan when the fan itself probably draws more than 2A, so I don't see that it would be the fan causing the problem. Could it be the controller itself? I'm kinda stumped here and don't know what to try next.

I've had the boiler for 3 years so I suppose it is covered under warranty, but I'm not sure what to ask to have replaced.

Any suggestions would be appreciated.

David

After a bit of troubleshooting I found that the fuse on the RK-2001UA controller had blown. When I replaced the fuse and tried to turn the furnace on, the display briefly flashed on and the fuse immediately blew again. I then disabled the pump and draft fan. This time the firebox fan came on, the controller lit up and stayed on and seemed to operate correctly, including all the functions on the controller. I then plugged in the draft fan and the fuse immediately blew again. After going to town to purchase more of the rather uncommon GMA glass fuses, I tried it again, this time with the firebox blower and the circ pump wired in, and only the draft fan disabled. Again everything seemed to work until I again applied the draft fan...BAM!...fuse blew again!

The draft fan itself works just fine when I apply line voltage to it directly. I don't have a lot of electrical knowledge, but it seems odd to me that this fuse, being just a 2A fuse, is blown by the current draw of the draft fan when the fan itself probably draws more than 2A, so I don't see that it would be the fan causing the problem. Could it be the controller itself? I'm kinda stumped here and don't know what to try next.

I've had the boiler for 3 years so I suppose it is covered under warranty, but I'm not sure what to ask to have replaced.

Any suggestions would be appreciated.

David

Last edited: