Good day everyone. I had posed on a previous thread (see below) a small introduction but wanted to formally start a thread about our wood pellet mill in Mattawamkeag, Maine. If you are reading this for the first time my name is David Kidwell and I am one of of the founders of Pinetree Pellet Fuels. We will be specializing in manufacturing premium softwood wood pellets from locally sourced and cleaned wood chips right here in Maine.

https://www.hearth.com/talk/threads/new-maine-pellet-mill.142172/

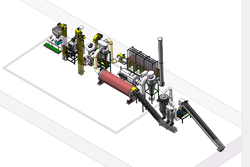

We will be a small scale, 2 tons per hour mill, with two complete 1 ton per mills. We are going this route for redundancy so if one mill goes down we will have another still operational. I have read the above thread posted here on Hearth.com and hope to clear up some confusion or misinformation with my post as we go along the journey to pushing the start button on day 1 of full operation.

I would like to thank Jim (webfish) at Hearth.com for letting us share this journey with all you wood pellet fanatics like myself

To start off I love my Quadrafire Mt. Vernon stove bought it back in 08', I believe, and had an issues with the heat plate cracking and flaking, but Quadrafire was aware of the issue, was the first year for the Mt Vernon if I remember correctly, and we got a replacement with no issues and no issue with the stove since. At one point we heated a 2,700sqft house with it and never used a drop of oil. Anyway enough about the stove back to the mill.

If you click the link above you can get some info from the local paper in the area who has been covering the mill and the steps as we go along the process. I will say there has been some misinformation in the papers as well, but when quoting a 3rd party sometimes that can happen. Nothing bad, just some dates and numbers were incorrect. No biggie in my book.

There are a few things that will different from our pellet mill then some of the big guys and that I will discuss down the road. What I will clear up now is that we will not be shipping a single pellet from our mill overseas. Made in the USA and we plan on keeping them here. So we can squash that assumption. Also the fact we have a purchase contract to pay 1/2 now and 1/2 one year later is cause lack of cash is also someone reading to much into what they read and not knowing the details of the agreement between the town and Pinetree Pellet Fuels. Always fun to watch people speculate, and I might of thought that to, but lack of cash is not the case with PTPF.

I have never blogged so this first post may seem boring but it is a brief introduction to the making of a wood pellet mill. I will be posting updates and pictures as we move along in the process of building the mill. I will try to keep you up to date as possible and if there is a lot of interest in following the mill setup process then maybe daily updates will be needed. I think the fun part will be interacting with you all and your thoughts, we will have a small lab mill where we will be trying different combinations of biowaste to see what we can get the most heat out of. Will be un.

un.

Well for now that is about all, check out the link above for some other info i might of missed and I post later tonight with what the inside of our mill looks like now, pre pellet mill.

David

https://www.hearth.com/talk/threads/new-maine-pellet-mill.142172/

We will be a small scale, 2 tons per hour mill, with two complete 1 ton per mills. We are going this route for redundancy so if one mill goes down we will have another still operational. I have read the above thread posted here on Hearth.com and hope to clear up some confusion or misinformation with my post as we go along the journey to pushing the start button on day 1 of full operation.

I would like to thank Jim (webfish) at Hearth.com for letting us share this journey with all you wood pellet fanatics like myself

To start off I love my Quadrafire Mt. Vernon stove bought it back in 08', I believe, and had an issues with the heat plate cracking and flaking, but Quadrafire was aware of the issue, was the first year for the Mt Vernon if I remember correctly, and we got a replacement with no issues and no issue with the stove since. At one point we heated a 2,700sqft house with it and never used a drop of oil. Anyway enough about the stove back to the mill.

If you click the link above you can get some info from the local paper in the area who has been covering the mill and the steps as we go along the process. I will say there has been some misinformation in the papers as well, but when quoting a 3rd party sometimes that can happen. Nothing bad, just some dates and numbers were incorrect. No biggie in my book.

There are a few things that will different from our pellet mill then some of the big guys and that I will discuss down the road. What I will clear up now is that we will not be shipping a single pellet from our mill overseas. Made in the USA and we plan on keeping them here. So we can squash that assumption. Also the fact we have a purchase contract to pay 1/2 now and 1/2 one year later is cause lack of cash is also someone reading to much into what they read and not knowing the details of the agreement between the town and Pinetree Pellet Fuels. Always fun to watch people speculate, and I might of thought that to, but lack of cash is not the case with PTPF.

I have never blogged so this first post may seem boring but it is a brief introduction to the making of a wood pellet mill. I will be posting updates and pictures as we move along in the process of building the mill. I will try to keep you up to date as possible and if there is a lot of interest in following the mill setup process then maybe daily updates will be needed. I think the fun part will be interacting with you all and your thoughts, we will have a small lab mill where we will be trying different combinations of biowaste to see what we can get the most heat out of. Will be

un.

un. Well for now that is about all, check out the link above for some other info i might of missed and I post later tonight with what the inside of our mill looks like now, pre pellet mill.

David