M

mikefrommaine

Guest

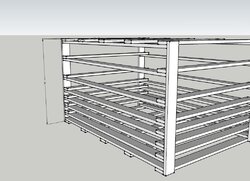

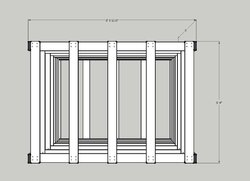

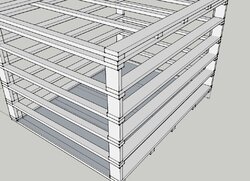

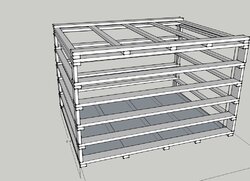

I have been playing around with ideas for a plywood tank. I would like to make a tank that fits in a storage area that I have. I have roughly 6.5' by 8.5' to work with. I'm a carpenter so plywood and framing lumber are my materials of choice. Here is a quick sketchup drawing of what I am considering for the tank structure. Based loosely on the BIS storage tank design.

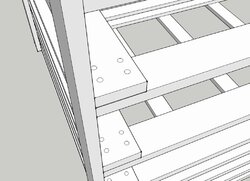

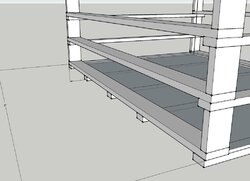

As drawn I have 2x6 and 2x4 side supports overlapping at the corners. There would be sleepers on the bottom bolted to the bottom and top side supports to prevent it from spreading in one direction. Plywood screwed to the sleepers would prevent spreading in the other direction (top and bottom).

The tank would be lined with plywood, rigid foam and a liner (epdm or pvc) Everything would be glued and screwed or bolted.

The short upright 2x6 spacers would be to support the frame work until the plywood is installed.

Ideally I would like to have a tank depth of 5' -- not sure if this design is capable of that? Thoughts? Critiques?

Thanks in advance.

As drawn I have 2x6 and 2x4 side supports overlapping at the corners. There would be sleepers on the bottom bolted to the bottom and top side supports to prevent it from spreading in one direction. Plywood screwed to the sleepers would prevent spreading in the other direction (top and bottom).

The tank would be lined with plywood, rigid foam and a liner (epdm or pvc) Everything would be glued and screwed or bolted.

The short upright 2x6 spacers would be to support the frame work until the plywood is installed.

Ideally I would like to have a tank depth of 5' -- not sure if this design is capable of that? Thoughts? Critiques?

Thanks in advance.

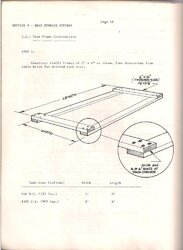

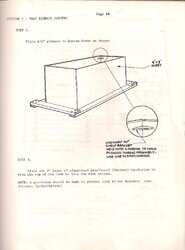

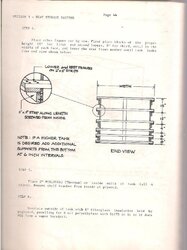

These are the instruction for constructing your own tank these came with our boiler. Two things that I would do different. For your planned height of 5', keep the 6" spacing until you are within 36" inches of the top, and for your planned width of 6' 5", follow the framing pattern for the sides on the ends also.

These are the instruction for constructing your own tank these came with our boiler. Two things that I would do different. For your planned height of 5', keep the 6" spacing until you are within 36" inches of the top, and for your planned width of 6' 5", follow the framing pattern for the sides on the ends also.