Hi All

Great site wish I found it a few years ago, forum sites like this are priceless for knowledge and information.

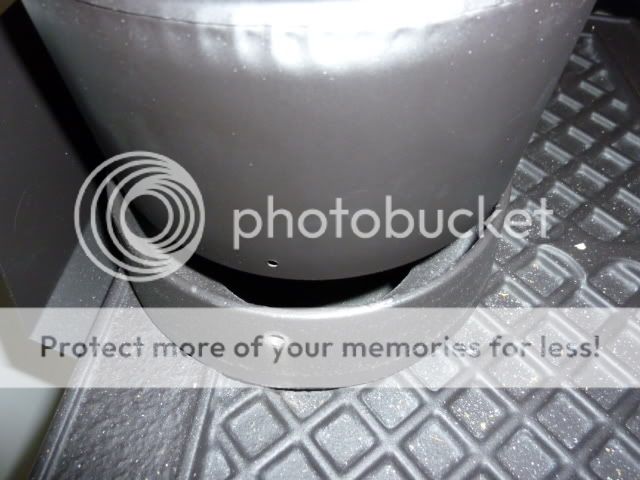

I'm a DIY so I'm going to try and doc. the whole process for your entertainment(pic's) and for you help answer all my dumba$$ ?'s and not screw up too bad.

Alitte history/backround

I have an small older home(40's), was pretty much a time machine when I bought it. 3rd owner, 2nd owner didn't do much except replace the electrical panel & cover it with vinyl.

I've added insulation, replaced all 21 windows, gut'd down to the stud's the 1 bathroom and tiled it back up. (Took 14 days straight, link drop http://www.johnbridge.com/ is another great site for tile advise.) And a number of other projects completed.

So for this one

Material collected - I updated as I go, I'm sure I'll be going to various B/B and Hardware stores to complete this one.

Jotul Nordic QT

SuperVent Ceiling Support Kit Model #: JSC6DCSP

SuperVent DSP6-6 Vertical Installation Kit Model #: DSP6VIK

SuperVent 6" x 36" Stainless Steel Chimney Pipe Model #: JSC6SA3

SuperPro JSC6RRS 6" Superpro Rafter Shield

Metalbest 6TAF-12 Sure-Temp 6" Class A Chimney Pipe Adjustable Roof Flashing for 6/12 to 12/12 Roof Pitch

Locking bands

Hight Temp Spray paint

and misc. stuff

Stove will be installed in my living room. Everything is going straight up, 1st through the ceiling then 5-6ft of attic space, and then the roof, should be justoff the peak.

Concern's so far are.

After dry fitting the vent conn. in the barn. I'm not that impressed with quality of these connections so RTV and/or Purpose specific GOO will be applied were needed.

?????

What's the best method for this?

RTV

Stove Gasket Cement

Other?

Thanks

Great site wish I found it a few years ago, forum sites like this are priceless for knowledge and information.

I'm a DIY so I'm going to try and doc. the whole process for your entertainment(pic's) and for you help answer all my dumba$$ ?'s and not screw up too bad.

Alitte history/backround

I have an small older home(40's), was pretty much a time machine when I bought it. 3rd owner, 2nd owner didn't do much except replace the electrical panel & cover it with vinyl.

I've added insulation, replaced all 21 windows, gut'd down to the stud's the 1 bathroom and tiled it back up. (Took 14 days straight, link drop http://www.johnbridge.com/ is another great site for tile advise.) And a number of other projects completed.

So for this one

Material collected - I updated as I go, I'm sure I'll be going to various B/B and Hardware stores to complete this one.

Jotul Nordic QT

SuperVent Ceiling Support Kit Model #: JSC6DCSP

SuperVent DSP6-6 Vertical Installation Kit Model #: DSP6VIK

SuperVent 6" x 36" Stainless Steel Chimney Pipe Model #: JSC6SA3

SuperPro JSC6RRS 6" Superpro Rafter Shield

Metalbest 6TAF-12 Sure-Temp 6" Class A Chimney Pipe Adjustable Roof Flashing for 6/12 to 12/12 Roof Pitch

Locking bands

Hight Temp Spray paint

and misc. stuff

Stove will be installed in my living room. Everything is going straight up, 1st through the ceiling then 5-6ft of attic space, and then the roof, should be justoff the peak.

Concern's so far are.

After dry fitting the vent conn. in the barn. I'm not that impressed with quality of these connections so RTV and/or Purpose specific GOO will be applied were needed.

?????

What's the best method for this?

RTV

Stove Gasket Cement

Other?

Thanks