I still remember the night last year in January where it was 15° out and my house temperature was plummeting past 50° because my boiler system was in a catastrophic failure. Thanks go you guys I gained the knowledge to realize I did a lot of things wrong.

This year I have moved my OWB 100ft closer to address a few issues and I currently experience minimal T Delta between the boiler and my heat exchanger where last year the delta was as great as 40°. I can now achieve 190° temp at my HX should I want it. Shoulder season was awesome. We enjoyed some really nice comfortable internal climate. Each of the last three years I have gone through 12 tightly packed cords by volume and this year I have gone through maybe 2-3 max so I’m expecting at least 30% less wood consumption.

I still believe I’m not getting the optimum heat exchange into my process water. I believe my delta is as much as 25° and I will admit I have a tough time gaining accurate readings since my only method to monitor is shooting copper pipe surface with an IR or the oil boiler temp gage in the house. I think I have two major issues being process water circ pump sizing and also my process water goes through the oil boiler prior to returning to the HX causing heat loss up the chimney.

I’m at the point where I want to invest in updating the process water system. My long term plan is to install storage, but it isn’t happening as soon as I thought, but I believe I can move forward with a system like shown in the sticky above while gaining efficiency and add storage later.

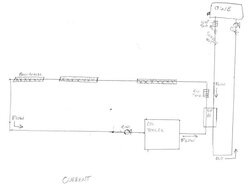

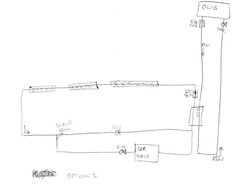

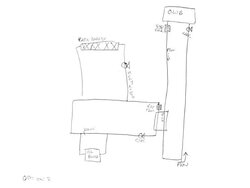

I’ve attached my current system along with two options I think are good options that I would like feedback on if you don’t mind. I will be more than happy to provide any additional information. Please keep in mind I did not add on all details like mixing valve for return to boiler.

Thank you in advance for your time!

This year I have moved my OWB 100ft closer to address a few issues and I currently experience minimal T Delta between the boiler and my heat exchanger where last year the delta was as great as 40°. I can now achieve 190° temp at my HX should I want it. Shoulder season was awesome. We enjoyed some really nice comfortable internal climate. Each of the last three years I have gone through 12 tightly packed cords by volume and this year I have gone through maybe 2-3 max so I’m expecting at least 30% less wood consumption.

I still believe I’m not getting the optimum heat exchange into my process water. I believe my delta is as much as 25° and I will admit I have a tough time gaining accurate readings since my only method to monitor is shooting copper pipe surface with an IR or the oil boiler temp gage in the house. I think I have two major issues being process water circ pump sizing and also my process water goes through the oil boiler prior to returning to the HX causing heat loss up the chimney.

I’m at the point where I want to invest in updating the process water system. My long term plan is to install storage, but it isn’t happening as soon as I thought, but I believe I can move forward with a system like shown in the sticky above while gaining efficiency and add storage later.

I’ve attached my current system along with two options I think are good options that I would like feedback on if you don’t mind. I will be more than happy to provide any additional information. Please keep in mind I did not add on all details like mixing valve for return to boiler.

Thank you in advance for your time!