Looking at various flat plate heat exchangers ....so far the only differences I see are in price and build material. Has anyone got any input on what to look out for on these items? Thx as always, RH

Flat Plate Heat Exchangers - Differences?

- Thread starter headrc

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

WoodNotOil

Minister of Fire

Here is the brand that I purchased: http://www.radiantheatproducts.com/store/cart.php?m=product_list&c=14 It appears to be the exact same construction and material as the more expensive ones I have seen in other systems. I am about to hook it up and try it in the next few days. I will let you know how it operates when I do.

Hi ...Thx for the response and the link. I have another question regarding this ....how did you size the heat exchanger to your application? RH

WoodNotOil

Minister of Fire

I called them and talked it over with their tech. He was very helpful. The 30 plate will transfer the 140,000 btus that my Tarm 40 puts out if the water moves at 15 gpm. You can probably go up or down in size based on your btu rating using mine as a baseline. Take a look at the tank design page on my website (in my signature).

jebatty

Minister of Fire

I started with (approx) 8" x 3" x 2" - 20 plate and found in my setup that did not seem to be able to carry the full Tarm 40 output; in other words, idling occurred more frequently than I thought desirable.

I changed that out to a (approx) 12" x 4" x 3" - 30 plate, with 1" inlets and outlets, and performance greatly improved.

Checkout ebay prices. Last summer got mine for just over $200. The brand was AIC, which appears to be an established mfr.

I changed that out to a (approx) 12" x 4" x 3" - 30 plate, with 1" inlets and outlets, and performance greatly improved.

Checkout ebay prices. Last summer got mine for just over $200. The brand was AIC, which appears to be an established mfr.

WoodNotOil

Minister of Fire

Redox

Minister of Fire

in hot water

New Member

Like any product there are good better and best options. If you find a price to good to be true, there may be a reason. I have seen some very low quality import components on the market these days. Material quality and workmanship suffer when you shop for lowest price, many times.

But some of the big name manufactures are going overseas for production and assembly. Usually a big name company will own or operate the overseas factory to assure the quality stays high. Viessmann is one example of a top line product that produces some components in China, as does B&G;. But they do control the product carefully.

I'd shop a reputable brand from a company that can answer questions and support the product should a problem arise. You won't know until it is all piped in as to the performance and quality, often times.

hr

But some of the big name manufactures are going overseas for production and assembly. Usually a big name company will own or operate the overseas factory to assure the quality stays high. Viessmann is one example of a top line product that produces some components in China, as does B&G;. But they do control the product carefully.

I'd shop a reputable brand from a company that can answer questions and support the product should a problem arise. You won't know until it is all piped in as to the performance and quality, often times.

hr

I may be replacing my Heat Exchanger ...any more input on this topic when considering a particular manufacturer? I currently have an AIC 30 plate ...and I am thinking of going for more plates ....so want to consider other manufacturers and pricing at this time.

jebatty

Minister of Fire

Number of plates, size of plates, port size, psi pressure drops Side A and Side B at various flow rates; approach temperatures -- all are critical information. You need to make this choice carefully. I have seen people choosing a plate hx of, for example, 230,000 btuh rating, but this being based on, for example, 30 or more gpm's. Pressure drop at these flow rates is astronomical and highly probable that such a plate hx would not work in a typical wood boiler application.

Thx ...so in adding 10 more plates .....I will be faced with really having re-analyze my system? Did not think adding that small amount would offer that much of a challenge

jebatty

Minister of Fire

I'm not saying what you plan will not work. All I am saying is that picking a plate hx is more involved than what might be apparent.

Hiya again ...well agin I have been using a 30 plate for three years now ...but am thinking of replacing it with a 40 plate hoping to get a little more efficiency in heat exchange. Also ...I am really curious about difference in manufacturers ....I see some pretty interesting pricing on some of them ...with all the same specs. So ....what is the difference? Same quality materials etc. ....and a difference in price of $200??? Is that the old "to good to be true" syndrome .....or are they all in about the same performance and endurance capacity ....

SmokeEater

Feeling the Heat

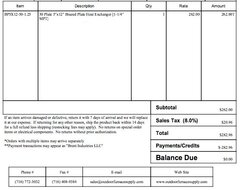

Agree completely with jebatty. Choosing the HX that "fits" take some study of pressure drops, flows, delta Ts, and etc. I found a very nice fit for my job at Outdoor Furnace Supply earlier this year for a brazed plate HX in 5" x 12", 50 plate and 1 1/4" MPT connections. The exchanger is not yet installed but is soon to be. After reading the posts here I thought the prices at OFS would beat those I saw, but went back to their site and can't find the same HX I bought for about $283 free shipping. Inflation I guess.

see

see

Attachments

I of course agree on the sizing aspect ...but two things ...adding ten plates makes that much of a difference to have to re-analyze all that data? Secondly ...even more important at this time .....is there a big difference between manufacturers ...I mean even if I want to just replace my current heat exchanger with the same exact specs ....I am seeing a wide difference in pricing.

SmokeEater

Feeling the Heat

Ten plates and the overall size of the HX can make a fairly large difference in specs between HXs. Material of manufacture, pressure specs, methods of brazing/welding all have large parts to play in costs. The HX I bought earlier this year has been replaced with another at a price increase of over $140.

JrCRXHF

Burning Hunk

I just got my system up and running this past weekend i went with a 70 Plate Brazed Heat Exchanger, 5" x 12", 1-1/4" MNPT ports.

Really good delta T on the unit which is what i was going after.

I paid 340.00 for it.

Really good delta T on the unit which is what i was going after.

I paid 340.00 for it.

SmokeEater

Feeling the Heat

Anyone here have input on the Brazetek heat exchangers ....pricing is pretty aggressive ....but does that mean quality suffers?

bpirger

Minister of Fire

One thing to consider is the temperature approach on both sides, i.e. if you have boiler water at 140, how warm will you get on the other side? 130? 125? 135? With my Garn and radiant heat, I wanted to be sure to be able to get very close, that way I can keep heating the floors when the Garn drops down to 130...120...in that range. I wound up with an 80 plate 5x12 with the 1 1/4" fittings....GEA is it? I think that's the right company..... I think it was $425 or so, so the above 70 plate is in the same ballpark. My approach temperatures are 3 degrees....so I get 127 on the house side when the temp in is 130. I'm happy with that!

Don't forget to plan on insulating the beast when you do the install....I bet I'm losing heat there as I have it enclosed in a 2" polystyrene "box" very losely held together....wrapped in R30 fiberglass. Not a good job at all....I bet some mice might have a really nice, warm home!

Also, don't forget the strainers....and better yet, install fittings so you can easily purge the strainers and run "outside" water through the exchanger itself to flush it out. I say that....but I've been online for 13.5 months, and I have yet to flush! Though I did measure the 3 degree approach last week....so I know I'm still doing good.

I have an 00R feeding both sides of the exhanger....not much pump really. To me this, like buried lines, isn't a place to skimp....an extra $100 can get you everything you could want...and you don't have to do it again!

Don't forget to plan on insulating the beast when you do the install....I bet I'm losing heat there as I have it enclosed in a 2" polystyrene "box" very losely held together....wrapped in R30 fiberglass. Not a good job at all....I bet some mice might have a really nice, warm home!

Also, don't forget the strainers....and better yet, install fittings so you can easily purge the strainers and run "outside" water through the exchanger itself to flush it out. I say that....but I've been online for 13.5 months, and I have yet to flush! Though I did measure the 3 degree approach last week....so I know I'm still doing good.

I have an 00R feeding both sides of the exhanger....not much pump really. To me this, like buried lines, isn't a place to skimp....an extra $100 can get you everything you could want...and you don't have to do it again!

Marginal flat plate sizes are touted by the same salesmen that say the 1" pipe is enough to feed adequate heat to a big old house and shop 300' away.

Short money up front often (but not always) means less performance for the life of the system.

Makes a tough call for the system owner that has to pay for it.

Short money up front often (but not always) means less performance for the life of the system.

Makes a tough call for the system owner that has to pay for it.

jebatty

Minister of Fire

The first plate hx I ought was about 3" x 8" x 30 plate, 3/4" ports, with statement that it could move 240,000 btuh. Well it could, with about a 100F delta-T and 40 gpm, pressure drop 20 psi, might be exaggerating a little, but to make the point. Picking a plate hx takes careful research, learning, or dealing with someone who really understands how they work and how to size them in a hydronic system.

Ok folks ...I appreciate all the variables everyone keeps emphasizing ...and I do understand them. I have been using a 30 plate 1" MPT 5x12 AIC exchanger for three years now ....and am fairly satisfied but since I now have to do some re-piping to implement a flushing system for it (an over site on my part previously) ...I am seriously contemplating increasing the number of plates to 40 plates. What I really want to get a handle on is difference in quality between manufacturers .......I mean the FlatPlate brand is high end, AIC seems mid stream and then all the Chinese of course are low end when it comes to price ....DOES ANYONE HERE HAVE A REFERENCE FOR THESE LOWER PRICED HEAT EXCHANGERS? That is what I am trying to get a handle on .....the materials are the same, the designs seem to be very similar ...if not the same ....how much is there to manufacturing these things? Has anyone experienced the Chinese/cheaper possibly degrading leaking etc. over time??

heaterman

Minister of Fire

BPirger and Jbeatty have hit the nails on the head......or heads........as there are several factors to consider when selecting a HX. Hot Rod also has an excellent "buyer beware" piece of advise. There is a LOT of really low quality junk hitting the market as people figure out who and how to deal with companies in China. I saw one supposedly stainless steel HX that rotted out in a little over a year. I don't remember the brand but I do remember that the "stainless steel" sparked when the owner touched it with an angle grinder.

I generally use AIC but have also installed GEA and Swep units. Flat Plate is the industry standard but there is no good source of supply near me.

The claims of 140,000 out of a 10 plate 5" x 12" model are true but as Jim pointed out, at what temp drop, flow rate and pressure drop. I'll just say that the smallest I recall installing was a 5x12-50 and that was for a fairly small house. Maybe 1,500 sq ft + domestic hot water. I like to shoot for temp differential from side A to B of less than 10* and preferably closer to 5. I have a few jobs out there on the commercial or very large residential side of things running with 10x20-50 or more. Loads on those are over 400,000btu peak demand.

I generally use AIC but have also installed GEA and Swep units. Flat Plate is the industry standard but there is no good source of supply near me.

The claims of 140,000 out of a 10 plate 5" x 12" model are true but as Jim pointed out, at what temp drop, flow rate and pressure drop. I'll just say that the smallest I recall installing was a 5x12-50 and that was for a fairly small house. Maybe 1,500 sq ft + domestic hot water. I like to shoot for temp differential from side A to B of less than 10* and preferably closer to 5. I have a few jobs out there on the commercial or very large residential side of things running with 10x20-50 or more. Loads on those are over 400,000btu peak demand.

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 3

- Views

- 333

- Replies

- 22

- Views

- 1K

- Replies

- 5

- Views

- 448