Has anyone ever wired a monitoring station. What I mean is a place, other than the boiler room, that I can monitor the system.

What I'm thinking is a board that will tell me if the wood burner or oil burner is running, what the supply and return temps are and what zones are calling.

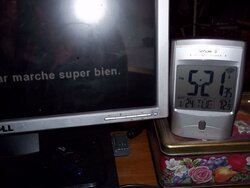

My situation is my oil burner is in the basement along with the Argo control box(which has lights that go one when a zone is on), the wood burner is out in the garage(which has a light go on when it is running), one t-stat is on the 1st floor and the other is on the second(which say "heat on" when the zone is on), I plan on getting the digital thermometers for supply and returns for each burner like I saw Clarkbug use. Also I have a RIB relay at each burner that has a light come on when the water temp is higher than the low limit setting. So I know which unit will be heating the water.

I am staying in good shape monitoring the system LOL. I either go in the back room where I can look through the window and see in the side garage door and see if the light is on for the WG. If it is, then I go to the other room, where I can see the chimney to see if is gasifing, then either I go to the basement to see if either zone is calling and if the relay light is on which would tell me the wood gun water is not high enough and the oil will go on, or I go to the t-stat on the first floor or run up stairs to the other t-stat to see if they are calling(only if I didnt go to the basement.)

Soooo, how could I wire up a board that I can keep in one room and see everything at once.

It would also help my wife know when to reload when I'm at work.

Hopefully I made sense and you understand what I'm looking to do. hh:

hh:

What I'm thinking is a board that will tell me if the wood burner or oil burner is running, what the supply and return temps are and what zones are calling.

My situation is my oil burner is in the basement along with the Argo control box(which has lights that go one when a zone is on), the wood burner is out in the garage(which has a light go on when it is running), one t-stat is on the 1st floor and the other is on the second(which say "heat on" when the zone is on), I plan on getting the digital thermometers for supply and returns for each burner like I saw Clarkbug use. Also I have a RIB relay at each burner that has a light come on when the water temp is higher than the low limit setting. So I know which unit will be heating the water.

I am staying in good shape monitoring the system LOL. I either go in the back room where I can look through the window and see in the side garage door and see if the light is on for the WG. If it is, then I go to the other room, where I can see the chimney to see if is gasifing, then either I go to the basement to see if either zone is calling and if the relay light is on which would tell me the wood gun water is not high enough and the oil will go on, or I go to the t-stat on the first floor or run up stairs to the other t-stat to see if they are calling(only if I didnt go to the basement.)

Soooo, how could I wire up a board that I can keep in one room and see everything at once.

It would also help my wife know when to reload when I'm at work.

Hopefully I made sense and you understand what I'm looking to do.

hh:

hh:

!

!