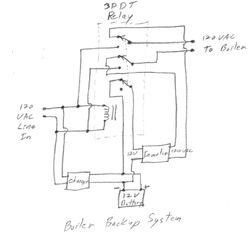

I haven't seen this mentioned in any of the threads I've read on battery backup for boiler controls and circulators, so here goes. I changed my backup from a 400 watt modified sine wave inverter operating on a 12V battery, which require manual switchover, to an 800VA UPS computer style backup operating on 24 VDC (2 x 12 volt batteries in series) which automatically switches over. I changed out the internal batteries to 2 - 104ah gel cells.

The good news is that on a power failure the switchover went fine, boiler continued to operate and circulators continoued to run, although the circulators (15-58, 009 and 007) emitted an audible buzz. The Kill-o-watt reported 111VAC; our normal line voltage is 120-122AC, and a little less than 400VA.

The bad news is that the UPS modified sine wave would not cold start the 15-58. I tried to start the system on the UPS backup, and the boiler controls lit up, the 15-58 emitted a buzz, but there was no flow. Speed setting was M, I switched it back and forth a couple of times between M and HI, and then it started. As best as I could tell the 009 and 007 started up OK.

I'm guessing either that the UPS could not provide sufficient start up current, or that the 15-58 doesn't like modified sine wave much at all, or both. From what I have been able to find is that motors will run hotter under modified sine wave and may emit a buzz, which these circs definitely did, and that modified sine wave may not be good for some motors.

Anyone else experience a similar issue? Or can try a cold start on the UPS and see if they have an issue? A pure sine wave UPS may be in my near future.

The good news is that on a power failure the switchover went fine, boiler continued to operate and circulators continoued to run, although the circulators (15-58, 009 and 007) emitted an audible buzz. The Kill-o-watt reported 111VAC; our normal line voltage is 120-122AC, and a little less than 400VA.

The bad news is that the UPS modified sine wave would not cold start the 15-58. I tried to start the system on the UPS backup, and the boiler controls lit up, the 15-58 emitted a buzz, but there was no flow. Speed setting was M, I switched it back and forth a couple of times between M and HI, and then it started. As best as I could tell the 009 and 007 started up OK.

I'm guessing either that the UPS could not provide sufficient start up current, or that the 15-58 doesn't like modified sine wave much at all, or both. From what I have been able to find is that motors will run hotter under modified sine wave and may emit a buzz, which these circs definitely did, and that modified sine wave may not be good for some motors.

Anyone else experience a similar issue? Or can try a cold start on the UPS and see if they have an issue? A pure sine wave UPS may be in my near future.