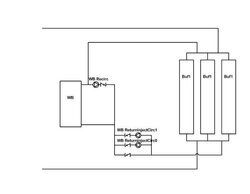

I'm not familiar with Tekmar controls.

Was reading a lot of good stuff on them on this forum, but I do have a question I don't know the answer to.

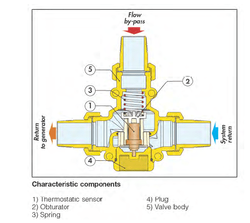

Is there a TEKMAR control or product that can be used as wood boiler return water temperature protection (like a Thermovar LK820)?

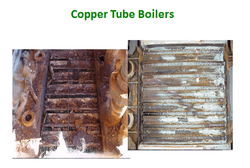

I have an issue with one of my indoor wood boilers installed in the field having excessive condensation and creosote build-up.

I do not have a detailed schematic or exact temperature readings, only bits and pieces.

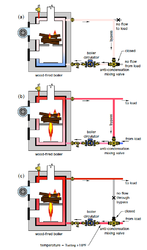

The wood boiler is charging a water storage tank.

The water storage feeds a floor radiant system

The water from the water storage tank is mixed down in temperature before it goes into the radiant manifold system

I do not know the temperaturess of the water entering/leaving the floor radiant manifold, but I know radiant floor systems run normally at temperatures between 80F-130F

I suspect that the return water from the radiant floor system is around 80-90F, and that this cold water is entering the storage tank and then gets fed into the wood boiler.

Don't quite understand how any of the TEKMAR controls can prevent this, that's why we always recommend and use a Thermovar LK820.

Any input is appreciated

Was reading a lot of good stuff on them on this forum, but I do have a question I don't know the answer to.

Is there a TEKMAR control or product that can be used as wood boiler return water temperature protection (like a Thermovar LK820)?

I have an issue with one of my indoor wood boilers installed in the field having excessive condensation and creosote build-up.

I do not have a detailed schematic or exact temperature readings, only bits and pieces.

The wood boiler is charging a water storage tank.

The water storage feeds a floor radiant system

The water from the water storage tank is mixed down in temperature before it goes into the radiant manifold system

I do not know the temperaturess of the water entering/leaving the floor radiant manifold, but I know radiant floor systems run normally at temperatures between 80F-130F

I suspect that the return water from the radiant floor system is around 80-90F, and that this cold water is entering the storage tank and then gets fed into the wood boiler.

Don't quite understand how any of the TEKMAR controls can prevent this, that's why we always recommend and use a Thermovar LK820.

Any input is appreciated