Hi all.

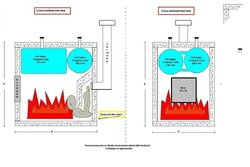

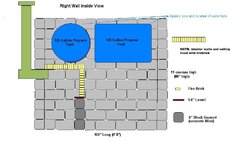

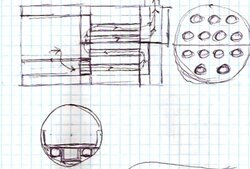

Attached are some diagrams of a boiler design I've been thinking of. I'm posting it to get as much criticism (the good and the bad) as possible before I build it. Please feel free to put in your $0.02 as often as you want. Thanks!

Attached are some diagrams of a boiler design I've been thinking of. I'm posting it to get as much criticism (the good and the bad) as possible before I build it. Please feel free to put in your $0.02 as often as you want. Thanks!