Hi Guys

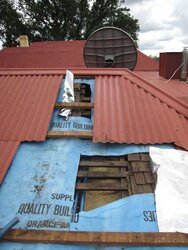

We are renovating our hydronics system, getting rid of the old boiler and getting a Seton

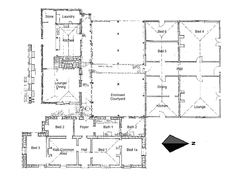

Our house is pretty large with 22 steel panel radiators rated at 50kw total. The house is old and cold, dont have any real figures on heat loss. We are at 900m and in winter it hovers between -2 at nights and 5 deg C in the day.

The goal is to be be able to start the fire morning and night and have storage to be able to cater for when the boiler has completed the burn. Maybe only once a day in the shoulder seasons. This seems to be very common over there in the US but here in Australia people don't seem to be doing it with local wood boilers. Our current wood boiler is a dog, needs to be fed every few hours or the house goes cold.

Alternatively the boiler will just burn for 8-10 hours while still providing adequate heat.... But I wonder if this is actually possible.

So the plan was to get a seton w180 and 3700 L (1000 gal) of open storage with a copper coil hx.

I got a million questions but I guess most pressing is...

- Will it work Would love to hear some opinions.

Would love to hear some opinions.

- What's a good plumbing setup for this, something simple with minimal hx in the storage.

- Assuming copper pipe in the storage, what's a good diameter and how to you determine the length

I am sure there is more but les see how that goes

Thanks !

!

David

We are renovating our hydronics system, getting rid of the old boiler and getting a Seton

Our house is pretty large with 22 steel panel radiators rated at 50kw total. The house is old and cold, dont have any real figures on heat loss. We are at 900m and in winter it hovers between -2 at nights and 5 deg C in the day.

The goal is to be be able to start the fire morning and night and have storage to be able to cater for when the boiler has completed the burn. Maybe only once a day in the shoulder seasons. This seems to be very common over there in the US but here in Australia people don't seem to be doing it with local wood boilers. Our current wood boiler is a dog, needs to be fed every few hours or the house goes cold.

Alternatively the boiler will just burn for 8-10 hours while still providing adequate heat.... But I wonder if this is actually possible.

So the plan was to get a seton w180 and 3700 L (1000 gal) of open storage with a copper coil hx.

I got a million questions but I guess most pressing is...

- Will it work

Would love to hear some opinions.

Would love to hear some opinions.- What's a good plumbing setup for this, something simple with minimal hx in the storage.

- Assuming copper pipe in the storage, what's a good diameter and how to you determine the length

I am sure there is more but les see how that goes

Thanks

!

!David