Hoval

Member

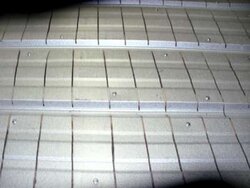

My ship has come in ! Or so the shipping website says, it is in the river between New York and New Jersey. No one has called me to tell me that my Pellet Mill is here but I am sure that I have the most important package on that whole ship. I have hired a company to get it through customs and to my transporter. This should be done by tonight or in a month or two. I will let you know. In the mean time I have been working on a storage power cooler that will hold between 5 and 6 tons of pellets and I will be able to cool pellets and dry them with forced air. I bought a 3' x 12' piece of metal roofing and cut slits across the width to allow air to be pushed up through the metal. I supported the underside with scrap strips of lumber so it will hold the weight and allow the air to go the full 12'. I will connect an old hot air furnace fan to the one end that could give me 4 speeds of air movement. I will probably start with just 2 speeds to start with. This will allow me to blow room air up through newly made pellets in my long term storage bin. I think that this will give me 12 weeks of pellets to get through in very cold weather. I will still have an extra ton in my daily hopper so make that 14+ weeks. I will take some picture's in the near future.

! Or so the shipping website says, it is in the river between New York and New Jersey. No one has called me to tell me that my Pellet Mill is here but I am sure that I have the most important package on that whole ship. I have hired a company to get it through customs and to my transporter. This should be done by tonight or in a month or two. I will let you know. In the mean time I have been working on a storage power cooler that will hold between 5 and 6 tons of pellets and I will be able to cool pellets and dry them with forced air. I bought a 3' x 12' piece of metal roofing and cut slits across the width to allow air to be pushed up through the metal. I supported the underside with scrap strips of lumber so it will hold the weight and allow the air to go the full 12'. I will connect an old hot air furnace fan to the one end that could give me 4 speeds of air movement. I will probably start with just 2 speeds to start with. This will allow me to blow room air up through newly made pellets in my long term storage bin. I think that this will give me 12 weeks of pellets to get through in very cold weather. I will still have an extra ton in my daily hopper so make that 14+ weeks. I will take some picture's in the near future.

! Or so the shipping website says, it is in the river between New York and New Jersey. No one has called me to tell me that my Pellet Mill is here but I am sure that I have the most important package on that whole ship. I have hired a company to get it through customs and to my transporter. This should be done by tonight or in a month or two. I will let you know. In the mean time I have been working on a storage power cooler that will hold between 5 and 6 tons of pellets and I will be able to cool pellets and dry them with forced air. I bought a 3' x 12' piece of metal roofing and cut slits across the width to allow air to be pushed up through the metal. I supported the underside with scrap strips of lumber so it will hold the weight and allow the air to go the full 12'. I will connect an old hot air furnace fan to the one end that could give me 4 speeds of air movement. I will probably start with just 2 speeds to start with. This will allow me to blow room air up through newly made pellets in my long term storage bin. I think that this will give me 12 weeks of pellets to get through in very cold weather. I will still have an extra ton in my daily hopper so make that 14+ weeks. I will take some picture's in the near future.

! Or so the shipping website says, it is in the river between New York and New Jersey. No one has called me to tell me that my Pellet Mill is here but I am sure that I have the most important package on that whole ship. I have hired a company to get it through customs and to my transporter. This should be done by tonight or in a month or two. I will let you know. In the mean time I have been working on a storage power cooler that will hold between 5 and 6 tons of pellets and I will be able to cool pellets and dry them with forced air. I bought a 3' x 12' piece of metal roofing and cut slits across the width to allow air to be pushed up through the metal. I supported the underside with scrap strips of lumber so it will hold the weight and allow the air to go the full 12'. I will connect an old hot air furnace fan to the one end that could give me 4 speeds of air movement. I will probably start with just 2 speeds to start with. This will allow me to blow room air up through newly made pellets in my long term storage bin. I think that this will give me 12 weeks of pellets to get through in very cold weather. I will still have an extra ton in my daily hopper so make that 14+ weeks. I will take some picture's in the near future.