Question for Progress Hybrid owners (cat screen)

- Thread starter 3fordasho

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

chipsoflyin

Member

chipsoflyin said:Yes, check on top of the baffle

Thanks! That is where it was, had it back in place in about 15mn, removed the top stone, stainless plate,cat, and then bypass door for easy access and re-install.

Back to regularly schelduled break in fires.

WarmInIowa

Member

Good idea, did you have help getting it off your truck? I assume it shipped in a crate. I'll find out soon, if it ever gets here. Was scheduled for Friday, but the terminal now says Monday. It's gonna be a cold weekend at my house! I've been sad for two days now with my Fireview taken out of service for the larger hearth install!

WarmInIowa said:Good idea, did you have help getting it off your truck? I assume it shipped in a crate. I'll find out soon, if it ever gets here. Was scheduled for Friday, but the terminal now says Monday. It's gonna be a cold weekend at my house! I've been sad for two days now with my Fireview taken out of service for the larger hearth install!

No help. The wife watched. Uncrated the PH on the back of my F150, used an engine hoist to lift off the crate base. Installed the roller base under the PH, the 2- 1/2" bolts on both ends allow raising or lowering the PH as required relative to the wheels. Used a set of reinforced 2x10 ramps to roll the PH from the back of the truck into the front door, only about a 6" drop over the length of the 8' ramps.

sam_j said:That IS a good idea. What diameter are the bolts- 1/2 or 5/8? And what size are the wheels? I'm supposed to be getting a PH in March so I may copy your idea, if you don't mind.

1/2-13 x6" length bolts on one end, use threaded rod on the other end, (otherwise you have to cut the bolts with a sawsall to get the board out from under the stove once it is in place). The wheels are 4" diameter with a 5.5" distance from the floor to the mounting plate of the wheels. I used all swivel wheels for maximum ability to shift position of the stove. The main board under the stove is a 2x12", the cross boards the wheels mount to are 2x6". Seems plenty sturdy to support the stove.

I did use a pair of ratchet straps to secure the stove to the 2x12.

Flamestead

Feeling the Heat

Here's pictures of the blocking under the stove from the factory. Picture two shows how it is designed to come apart by removing screws to allow you to install the legs while it is still sitting on the main part of the support. It was held on with two packing straps placed outside the shipping cardboard box. Once those straps are removed it is just gravity holding it there.

I moved the stove horizontally by skidding on planks, but needed help from my wife. If I had used rollers (or very nice wheels, like in this post) it could have been a one-person job. I lifted it vertically with blocks of wood and a small crowbar. Once in place with the legs on, I lifted the whole package an inch, blocked under the stove legs, let the factory blocking back down, and slide it out. Then, concerned about the legs, I did the only heavy lifting of the day - I lifted one end of the stove while my wife pulled out the blocking under the legs, and then repeated on the other end.

In my install thread from yesterday you can see the stove in place, still on the blocking.

(edited for spelling)

I moved the stove horizontally by skidding on planks, but needed help from my wife. If I had used rollers (or very nice wheels, like in this post) it could have been a one-person job. I lifted it vertically with blocks of wood and a small crowbar. Once in place with the legs on, I lifted the whole package an inch, blocked under the stove legs, let the factory blocking back down, and slide it out. Then, concerned about the legs, I did the only heavy lifting of the day - I lifted one end of the stove while my wife pulled out the blocking under the legs, and then repeated on the other end.

In my install thread from yesterday you can see the stove in place, still on the blocking.

(edited for spelling)

Attachments

Woody Stover

Minister of Fire

Nice! I might have to make up one of those to make it easy to swap stoves if I want to...3fordasho said:1/2-13 x6" length bolts on one end, use threaded rod on the other end, (otherwise you have to cut the bolts with a sawsall to get the board out from under the stove once it is in place). The wheels are 4" diameter with a 5.5" distance from the floor to the mounting plate of the wheels. I used all swivel wheels for maximum ability to shift position of the stove. The main board under the stove is a 2x12", the cross boards the wheels mount to are 2x6". Seems plenty sturdy to support the stove. I did use a pair of ratchet straps to secure the stove to the 2x12.

Is that the ash pan I can kind of see...there's still room for it with the short legs? I like the look of the PH (and the Fireview) with the short legs...stocky low-rider ready to kick some arse.

Backwoods Savage

Minister of Fire

Woody, I don't think the ash pan is available with the short legs. I agree that it does look better with the short legs.

week 2 update:

Last friday found one side of the cat screen laying in the firebox and the other hanging out of place and ready to fall. Let the stove cool down, re-positioned the screens and used a bit of high temp gasket cement/stove sealer on the little tabs that catch the front cast part of the stove... so far they are staying in place.

Performance wise the stove really throws the heat, average house temp is about 5 degrees higher over the fireview with similar reload times (more do to my schedule than the need to reload). I rarely see stove top temps over 500f, but at those temps the house would really be overheated... The need to run the 2nd stove is pretty much been eliminated. If I'm running both the entire house will be 80f.

Smoke smell.... I'm having this issue as others have reported. No visible smoke, smoke alarms or detection on the CO detector but the smell is there, the wife complains of a "burnt" smell in the house. Time to call woodstock to see about a different door gasket I guess. I have the left hand door option.

Short legs - really like the look with the short legs. I was worried about my hearth R-value but I'm seeing lower hearth temps than when the fireview was in it's place.

I also don't quite have the 24" clearance from the right side of the stove to a sheetrock wall.. again the wall temps are less then when the fireview stove was there with it's loading door facing that wall.

Bottom heat shield -- a bit tricky to install the last (3rd) bottom heat shield with the short legs.. I had to remove one of the legs and support the stove with a 2x4 from the hearth to the upper corner of the stove... then I could slip in the last heat shield.

Last friday found one side of the cat screen laying in the firebox and the other hanging out of place and ready to fall. Let the stove cool down, re-positioned the screens and used a bit of high temp gasket cement/stove sealer on the little tabs that catch the front cast part of the stove... so far they are staying in place.

Performance wise the stove really throws the heat, average house temp is about 5 degrees higher over the fireview with similar reload times (more do to my schedule than the need to reload). I rarely see stove top temps over 500f, but at those temps the house would really be overheated... The need to run the 2nd stove is pretty much been eliminated. If I'm running both the entire house will be 80f.

Smoke smell.... I'm having this issue as others have reported. No visible smoke, smoke alarms or detection on the CO detector but the smell is there, the wife complains of a "burnt" smell in the house. Time to call woodstock to see about a different door gasket I guess. I have the left hand door option.

Short legs - really like the look with the short legs. I was worried about my hearth R-value but I'm seeing lower hearth temps than when the fireview was in it's place.

I also don't quite have the 24" clearance from the right side of the stove to a sheetrock wall.. again the wall temps are less then when the fireview stove was there with it's loading door facing that wall.

Bottom heat shield -- a bit tricky to install the last (3rd) bottom heat shield with the short legs.. I had to remove one of the legs and support the stove with a 2x4 from the hearth to the upper corner of the stove... then I could slip in the last heat shield.

sheeplenot

New Member

That dolly you made is pretty cool.My progress will be here in 2 weeks and I was trying to figure out how to move it.I have access to a pallet jack do you think it would work?

sheeplenot said:That dolly you made is pretty cool.My progress will be here in 2 weeks and I was trying to figure out how to move it.I have access to a pallet jack do you think it would work?

Depends if your getting the short or standard legs. With the short legs there may not be enough distance from the floor to the bottom of the stove to get the jack forks underneath. I know a 2x12 fits underneath between the legs, that's 1.5", possibly could have fit another but I know there is not 5" there.

Waulie

Minister of Fire

sheeplenot said:That dolly you made is pretty cool.My progress will be here in 2 weeks and I was trying to figure out how to move it.I have access to a pallet jack do you think it would work?

I rented a pallet jack to move my Progress. The pallet jack I rented was for a standard pallet, but the pallet they use is not standard. The forks of the jack were too wide to fit in the grooves of the pallet. I still ended up using it by placing the one fork of the jack in one groove, jacking the stove up a bit, and blocking under it. Then the same thing on the other side. Then, I slid the forks under the bottom of the pallet. It worked, but not nearly as slick as I'd hoped.

sheeplenot

New Member

Waulie said:The pallet jack I rented was for a standard pallet, but the pallet they use is not standard. The forks of the jack were too wide to fit in the grooves of the pallet. I still ended up using it by placing the one fork of the jack in one groove, jacking the stove up a bit, and blocking under it. Then the same thing on the other side. Then, I slid the forks under the bottom of the pallet. It worked, but not nearly as slick as I'd hoped.

Dang I was hoping for a easy move. I guess much like you I will have to improvise when it gets here. %-P

This morning I noticed the cat screens are out of place again, must be the third or fourth time I've had to put them back in place. The last time I was 100% sure they were positioned correctly and in their slot. I think WS needs to come up with a postive way to fasten these in place. I guess it's time to let the stove go cold again and try the new set they sent me. The stove has almost spent more time cold than hot since I've installed. I have not noticed as much smoke smell lately but I also don't completely shut down the draft like I did before either - as a result I don't get the burn times like I think I should.. really they were better with the fireview.

On the plus side the house is always warmer, like 5degrees warmer than with the FV.

I hope I'm not screwing up the cat with these screens coming out of place because they are not catching the ash when out of position.

Like others have mentioned in the SS cat thread it is taking higher sustained temps to get it to light off and stay lit.

On the plus side the house is always warmer, like 5degrees warmer than with the FV.

I hope I'm not screwing up the cat with these screens coming out of place because they are not catching the ash when out of position.

Like others have mentioned in the SS cat thread it is taking higher sustained temps to get it to light off and stay lit.

rideau

Minister of Fire

Tim- When did they send you the new screen? Is it any different? I last spoke with them about three weeks ago about the screen, and they were working on a way to more positively attach the screen. Don't know whether they have come up with anything yet. My screen came with one side slightly damaged...the screening lower edge of screening is coming apart...so really cannot slide one piece over the other on installation. The first piece goes in fine, second piece I sort of seat and say a prayer. Woodstock advised bending the little tab a bit to get better installation. You might call and ask them about that...it may help yours to stay in place. Maybe they have already bent your replacement differently, though? I'll wait another week, then give them a call re the screen...

rideau said:Tim- When did they send you the new screen? Is it any different? I last spoke with them about three weeks ago about the screen, and they were working on a way to more positively attach the screen. Don't know whether they have come up with anything yet. My screen came with one side slightly damaged...the screening lower edge of screening is coming apart...so really cannot slide one piece over the other on installation. The first piece goes in fine, second piece I sort of seat and say a prayer. Woodstock advised bending the little tab a bit to get better installation. You might call and ask them about that...it may help yours to stay in place. Maybe they have already bent your replacement differently, though? I'll wait another week, then give them a call re the screen...

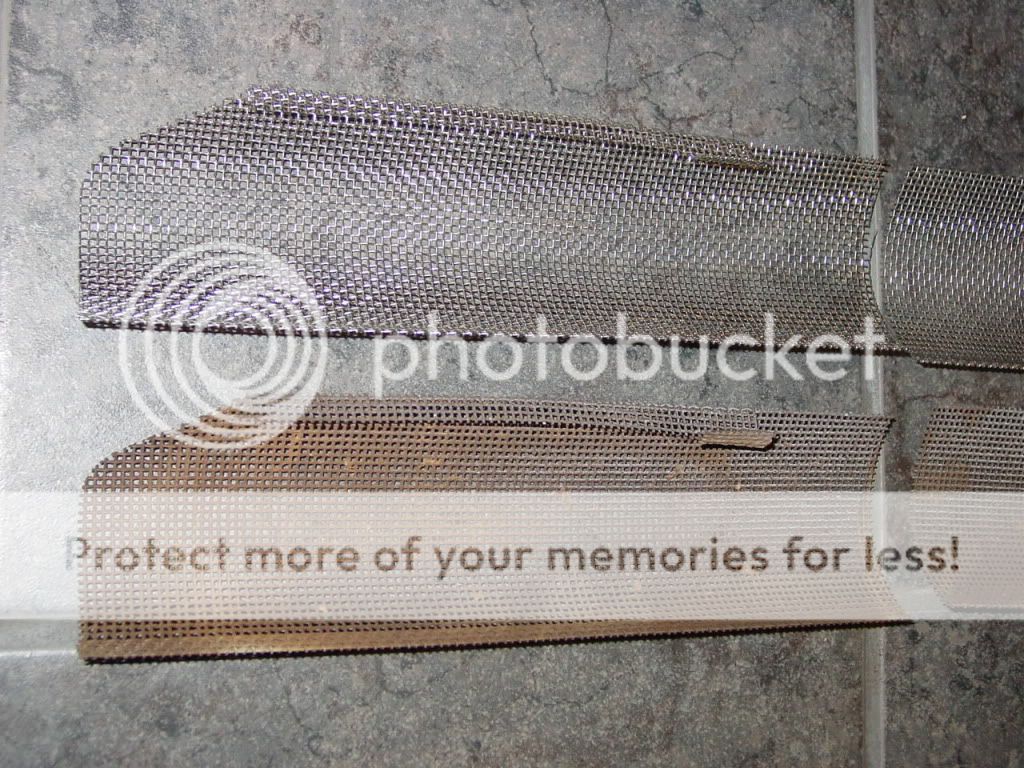

I received the screens about a week ago. Later today or tomorrow once the stove has cooled I'll take a pick off the old/new screens next to each other. I have not compared them side by side but from memory the new ones appear about the same as the old. The tabs on the new ones don't apprear to be bent as far as the old ones, perhaps they are bent further once installed?

So far the new screens are staying in place... that said I'll find them in the firebox when I get home later today ;-)

Besides replacing the screens I applied some hi-temp antisieze to the the rod that acts on the bypass plate, operation had become very noisy and rattled the stove abit.

It's better now, perhaps it was enough to rattle the screens out of place?

Besides replacing the screens I applied some hi-temp antisieze to the the rod that acts on the bypass plate, operation had become very noisy and rattled the stove abit.

It's better now, perhaps it was enough to rattle the screens out of place?

rideau

Minister of Fire

Tim, I'm not sure they are quite right. Hard to be sure, but it looks like the two screens are abutting, not overlapping? One is supposed to sit inside the other, then you are supposed to slide them apart and they are supposed to overlap..by about 1 inch, I think. Woodstock will e-mail you directions if you give them a call. One of my screens has a line of mesh pulled out at the bottom -came that way- and mine won't slide against each other. SO I had to put one in, which fit fine and sort of snapped into place. Then I could not for the life of me get the other in. SO I sort of propped it where it was supposed to be and called Woodstock to see if that was OK. They told me as long as it stays. It's been there for quite a while now. Checked the screen by flashlight while stove was cold about an hour ago. A few of the squares are full of ash, but just a few and the screen is such a pain that I'm not going to clean it until it gets worse. I figure why ask for trouble? But do check about the screen. I think if its not overlapping it may be more apt to fall...

rideau said:Tim, I'm not sure they are quite right. Hard to be sure, but it looks like the two screens are abutting, not overlapping? One is supposed to sit inside the other, then you are supposed to slide them apart and they are supposed to overlap..by about 1 inch, I think. Woodstock will e-mail you directions if you give them a call. One of my screens has a line of mesh pulled out at the bottom -came that way- and mine won't slide against each other. SO I had to put one in, which fit fine and sort of snapped into place. Then I could not for the life of me get the other in. SO I sort of propped it where it was supposed to be and called Woodstock to see if that was OK. They told me as long as it stays. It's been there for quite a while now. Checked the screen by flashlight while stove was cold about an hour ago. A few of the squares are full of ash, but just a few and the screen is such a pain that I'm not going to clean it until it gets worse. I figure why ask for trouble? But do check about the screen. I think if its not overlapping it may be more apt to fall...

Thanks for your input. I do have the instructions from woodstock and I believe they call for ~1/2" overlap. Mine do overlap but more like 1/8-1/4". I could get more overlap by sliding them closer together, but then I would have gaps on the outer ends? As long as they stay in place I'm calling it good ;-)

mliiiwit

Member

3fordasho said:So far the new screens are staying in place... that said I'll find them in the firebox when I get home later today ;-)

Besides replacing the screens I applied some hi-temp antisieze to the the rod that acts on the bypass plate, operation had become very noisy and rattled the stove abit.

It's better now, perhaps it was enough to rattle the screens out of place?

They are installed as mine originally were. I removed mine to clean for the first time tonight after burning since 2/14. Was able to get them in and out without problem without removing the bypass door.

What did you use for hi-temp anti sieze? C5A? How has it held up?

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 494

- Replies

- 11

- Views

- 2K

- Replies

- 6

- Views

- 935

- Replies

- 3

- Views

- 317