This is my first attempt at any kind of remodel so I thought I would keep a photo log and share it with the people who will undoubtedly play a big part in helping me along as I ask for ideas and advice. This site has already been a great source of information and ultimately the reason I took this project on as a DIY adventure.

Thanks in advance for your help and advice.

Here is what's coming out.

Here is where I stand today.

Actually, here is where I stand. The piece of plywood is the footprint of the new Fireview that is on the way.

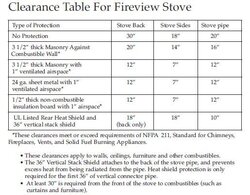

Now I need to design a hearth and figure out how to tie in the stove pipe to the existing structure.

Here we go.......

Colin

Thanks in advance for your help and advice.

Here is what's coming out.

Here is where I stand today.

Actually, here is where I stand. The piece of plywood is the footprint of the new Fireview that is on the way.

Now I need to design a hearth and figure out how to tie in the stove pipe to the existing structure.

Here we go.......

Colin

!!

!!