In my area there seems to be a vast quantity of defective Stihl chainsaw chain.

The defect is that the chain cutters (teeth) are ground is such a way that you are unable to sharpen the chain with a standard round file.

While I was at the dealer I noticed and pointed out the all the newer replacement chains as well as all the new chains mounted on new saws for sale had this same defect. This prompted my dealer to call other dealers in the area who reported the same issue with their inventories.

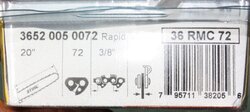

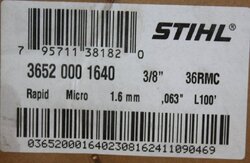

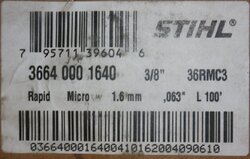

This defect has been found several sizes and types of chain.

If you are buying Stihl brand chain, be sure that you are able to correctly insert the proper sized round file into the cutters before you purchase the chain.

I was unaware of this problem when I bought my chain. Even after having the chain sharped one time at the dealer with a bench grinder, I am still unable to insert the proper sized round file at the correct depth for proper sharpening. This is a real vexing problem when you are out in the field and want to touch up the chain.

At this time I am not sure if the dealer has talked to the field rep about this issue.

The defect is that the chain cutters (teeth) are ground is such a way that you are unable to sharpen the chain with a standard round file.

While I was at the dealer I noticed and pointed out the all the newer replacement chains as well as all the new chains mounted on new saws for sale had this same defect. This prompted my dealer to call other dealers in the area who reported the same issue with their inventories.

This defect has been found several sizes and types of chain.

If you are buying Stihl brand chain, be sure that you are able to correctly insert the proper sized round file into the cutters before you purchase the chain.

I was unaware of this problem when I bought my chain. Even after having the chain sharped one time at the dealer with a bench grinder, I am still unable to insert the proper sized round file at the correct depth for proper sharpening. This is a real vexing problem when you are out in the field and want to touch up the chain.

At this time I am not sure if the dealer has talked to the field rep about this issue.

Roger, I hope you're ready.....

Roger, I hope you're ready.....