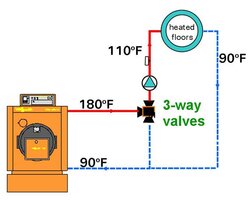

I just added a new set of radiant slab loops to my boiler. The closely spaced tees and everything had been there since install. The manifold consists of two cement slab loops--currently turned off due to other issues--and two fresh loops going to a tile floor on plywood and one under a laminate floor. Due to the laminate and slabs I have a mixing valve turned down to 80 degrees.

I filled the loops through the manifold, opened the valves to everything and then added more water/pressure to flush out any remaining air...... The first thing I noted was that the temp climbed way over 80. This loop draws off of the boiler return line so that it can always have access to water at least 100. At the moment the boiler is running and the return temps are maximum. The water to the manifold is hitting 120. But I see no climb on the return line. Neither do I feel any difference. I checked the line going to the cold side of the mixing valve and it seems fine.

The pump running this circuit is a Taco 007. The pump seems to be running very hot, even though the incoming side is cold and the discharge side is hottish. I have this loop set up to pull the water through the radiant loops.

Attached is a photo of this part of my system--it's on it's side..... I just can't figure out what's going on....the rest of the system is working fine--except, perhaps a slight leak in my storage tank which just developed (but we won't mention that just yet...). My much more complicated radiator system and all of it's loops came out of summer moth-balls just fine. This radiant thing has me stumped.

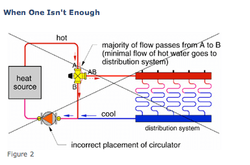

Could it be the pump placement?

I filled the loops through the manifold, opened the valves to everything and then added more water/pressure to flush out any remaining air...... The first thing I noted was that the temp climbed way over 80. This loop draws off of the boiler return line so that it can always have access to water at least 100. At the moment the boiler is running and the return temps are maximum. The water to the manifold is hitting 120. But I see no climb on the return line. Neither do I feel any difference. I checked the line going to the cold side of the mixing valve and it seems fine.

The pump running this circuit is a Taco 007. The pump seems to be running very hot, even though the incoming side is cold and the discharge side is hottish. I have this loop set up to pull the water through the radiant loops.

Attached is a photo of this part of my system--it's on it's side..... I just can't figure out what's going on....the rest of the system is working fine--except, perhaps a slight leak in my storage tank which just developed (but we won't mention that just yet...). My much more complicated radiator system and all of it's loops came out of summer moth-balls just fine. This radiant thing has me stumped.

Could it be the pump placement?