- Sep 20, 2012

- 44

Hey guys, I'm just curious how many of you have a setup with an elbow directly ontop of the stove to run back into the liner? I talked to an installer and he says he doesn't like the idea and it won't make enough heat that way but If I wanna install it that way he will come and inspect it. He said it's safe just not an install he wants to do due to possible poor draft and not throwing off enough heat.

So he just said he doesn't want me to be upset if my stove doesn't have good draft and blame him for it so he wants me to do it myself.

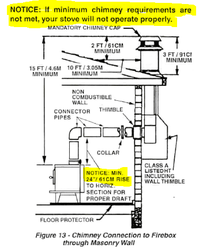

I have an interior chimney, with 25' of stainless double wall insulated smooth bore liner which will have a t termination at the bottom, 1' of horizontal pipe connecting the t termination to the elbow ontop of the stove with a couple inches of drop along that 1' section. Thanks for any experiences on if your system may work like this!

So he just said he doesn't want me to be upset if my stove doesn't have good draft and blame him for it so he wants me to do it myself.

I have an interior chimney, with 25' of stainless double wall insulated smooth bore liner which will have a t termination at the bottom, 1' of horizontal pipe connecting the t termination to the elbow ontop of the stove with a couple inches of drop along that 1' section. Thanks for any experiences on if your system may work like this!