Hey guys! Tis the season! Random question...throughout some issues last winter, you all gave one consistent piece of advice...and that was protection in the way of a 3 way mixing valve. I purchased one a couple weeks back, but haven't installed it yet. As I fired up the Orlan 60 for the first time this season, I noticed something I hadn't paid much attention to before....

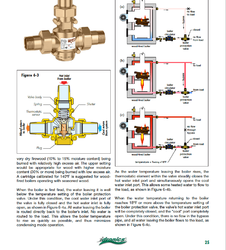

I've included three photos to look at. I've circled what I thought might be the mixing valve. The bottom arrow is the return to the back of the boiler. I choked that ball valve up above to send more water to the pumps. If I open it all the way up, it seems as though the water flows right by the pumps and I don't get much to them. If I choke it down, I had much more hot water flowing directly to the two pumps.

Any thoughts?

I've included three photos to look at. I've circled what I thought might be the mixing valve. The bottom arrow is the return to the back of the boiler. I choked that ball valve up above to send more water to the pumps. If I open it all the way up, it seems as though the water flows right by the pumps and I don't get much to them. If I choke it down, I had much more hot water flowing directly to the two pumps.

Any thoughts?

, hell, I would help you for a lot less if I was anywhere near Wyoming

, hell, I would help you for a lot less if I was anywhere near Wyoming