Hello all pyro friends,

I am posting this to let you know about my "designer" fireplace to masonry hybrid conversion, which is about 80% complete, with the cold season about a month away.

I hope I can get this finished by next weekend.

Basically, I took apart a stainless steel/ceramic glass 60 cm cube, and added a serious amount of firebrick to it, keeping the big glass front door and the metal structure intact.

The top of firebox has a built-in baffle made from firebrick and steel angle, and the rear side will still have 1/3 of glass for double sided view.

As soon as I finish it, I will post additional photos of the inside and maybe a movie of the first full burn (3-4 curing fires are in order first..).

It will feature enlarged primary air openings (it required an open door ignition for a few seconds) and secondary air steel tubes for testing purpose - note the cuts on the stainless steel front plate - this is not how it will look in the end...

Here are the pictures...

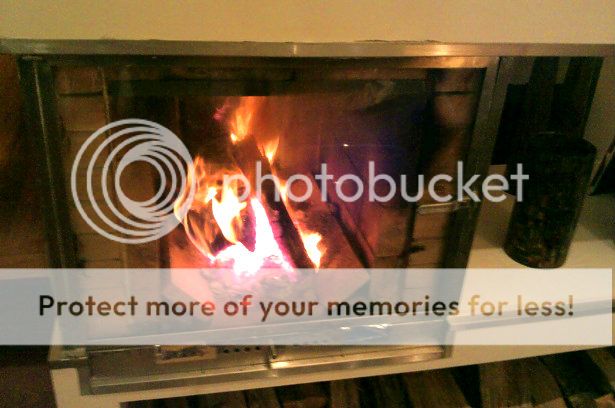

Last year's burning method with some firebricks inside (yes it's a top-down burn...):

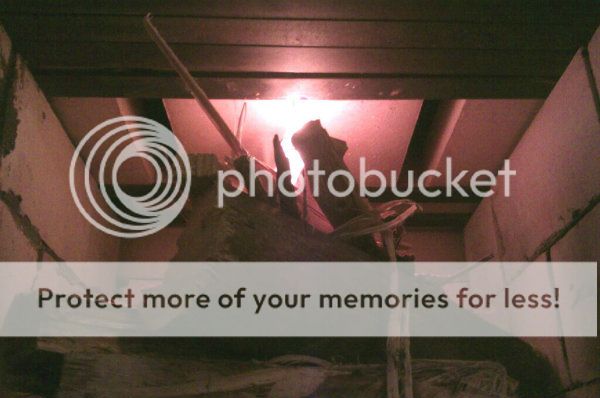

Fitting the bricks after removing side and rear glasses:

The rear side will have only 1/3 of the glass:

The rear side is now almost finished:

I expect to more than double the amount of heat we'll get from this fireplace this winter.

The firebrick will be covered in tile in the future, but I want to watch it for cracks during its first season.

Regards, Daniel from Portugal.

I am posting this to let you know about my "designer" fireplace to masonry hybrid conversion, which is about 80% complete, with the cold season about a month away.

I hope I can get this finished by next weekend.

Basically, I took apart a stainless steel/ceramic glass 60 cm cube, and added a serious amount of firebrick to it, keeping the big glass front door and the metal structure intact.

The top of firebox has a built-in baffle made from firebrick and steel angle, and the rear side will still have 1/3 of glass for double sided view.

As soon as I finish it, I will post additional photos of the inside and maybe a movie of the first full burn (3-4 curing fires are in order first..).

It will feature enlarged primary air openings (it required an open door ignition for a few seconds) and secondary air steel tubes for testing purpose - note the cuts on the stainless steel front plate - this is not how it will look in the end...

Here are the pictures...

Last year's burning method with some firebricks inside (yes it's a top-down burn...):

Fitting the bricks after removing side and rear glasses:

The rear side will have only 1/3 of the glass:

The rear side is now almost finished:

I expect to more than double the amount of heat we'll get from this fireplace this winter.

The firebrick will be covered in tile in the future, but I want to watch it for cracks during its first season.

Regards, Daniel from Portugal.

, I'll make sure I take some photos.

, I'll make sure I take some photos. ), and I just laughed at my statement "temperatures are dropping fast here"... never mind that...

), and I just laughed at my statement "temperatures are dropping fast here"... never mind that...