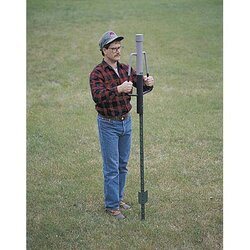

Trying to determine what length I need

Is driving them in 1ft deep enough ???

I was thinking 5ft post ,drive in 1ft, or 5 1/2 ft or 6ft ????

Going to put them at end of pallets

Is driving them in 1ft deep enough ???

I was thinking 5ft post ,drive in 1ft, or 5 1/2 ft or 6ft ????

Going to put them at end of pallets