- Dec 19, 2012

- 14

Newbie needs assistance....

I had a Tarm Solo Plus 40 (no storage) installed in the basement of a new construction 2 floor colonial with a bonus room above the garage. approx 2400 sq/ft. House is heated with baseboard units, garage and basement are not heated. I've never had a wood boiler before (moved from the city into the woods of New Hampshire). I've been playing with load size with the various outdoor temps. After two nights of not sleeping because it was 80 F in the upstairs during the night, I shut down the unit and am running on LP, not what I want to do but the wife is pregnant, so.....you know...happy wife, happy life. The temp on the first floor was 62-64 F. The outdoor temp during the night was approx 20 F. I have the valve set to open when the tank reaches 140 F, I have the fan speed running at approx 70%. the valve I'll call the safety valve is set to open if the tank gets to 200 F. The 2nd floor is the dump zone but temp in the tank has not gone over 200 F. Grundfos circulator pumps are set on high for the two zones on the first floor and low for the upstairs zone. When I went to bed I added 2-3 more pieces of wood in the fire box that was only coals.

This was the first Tarm for the installer so I had another guy who has installed several come and look at the set up and he told me it was correct, both plumbing and wiring. I was thinking about closing off the 2nd floor zone at night.

Any suggestions? Go easy on me, I'm just a rookie! I also have no training in plumbing or HVAC.

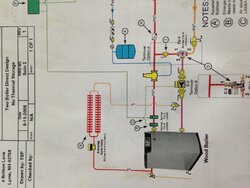

I will post photo's of wiring later tonight or tomorrow. Thanks in advance!

I had a Tarm Solo Plus 40 (no storage) installed in the basement of a new construction 2 floor colonial with a bonus room above the garage. approx 2400 sq/ft. House is heated with baseboard units, garage and basement are not heated. I've never had a wood boiler before (moved from the city into the woods of New Hampshire). I've been playing with load size with the various outdoor temps. After two nights of not sleeping because it was 80 F in the upstairs during the night, I shut down the unit and am running on LP, not what I want to do but the wife is pregnant, so.....you know...happy wife, happy life. The temp on the first floor was 62-64 F. The outdoor temp during the night was approx 20 F. I have the valve set to open when the tank reaches 140 F, I have the fan speed running at approx 70%. the valve I'll call the safety valve is set to open if the tank gets to 200 F. The 2nd floor is the dump zone but temp in the tank has not gone over 200 F. Grundfos circulator pumps are set on high for the two zones on the first floor and low for the upstairs zone. When I went to bed I added 2-3 more pieces of wood in the fire box that was only coals.

This was the first Tarm for the installer so I had another guy who has installed several come and look at the set up and he told me it was correct, both plumbing and wiring. I was thinking about closing off the 2nd floor zone at night.

Any suggestions? Go easy on me, I'm just a rookie! I also have no training in plumbing or HVAC.

I will post photo's of wiring later tonight or tomorrow. Thanks in advance!