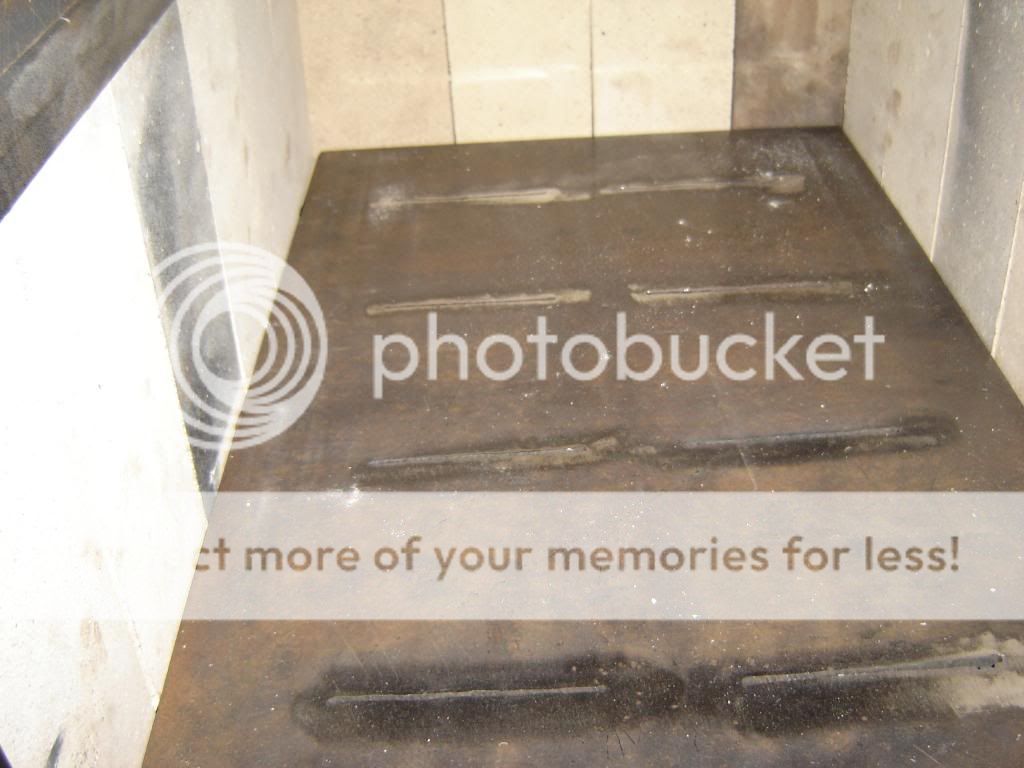

The trusty old wood stove has kept us warm for the last 12 years. Not too bad considering the 100 bux I paid for it + a few replacement bricks and gaskets over the years. Unfortunately, it's really showing it's age. It's a late '94 model I got from a navy buddy when he sold his house in '00.

I've been contemplating it's replacement for nearly 2 years, finally pulled the trigger.

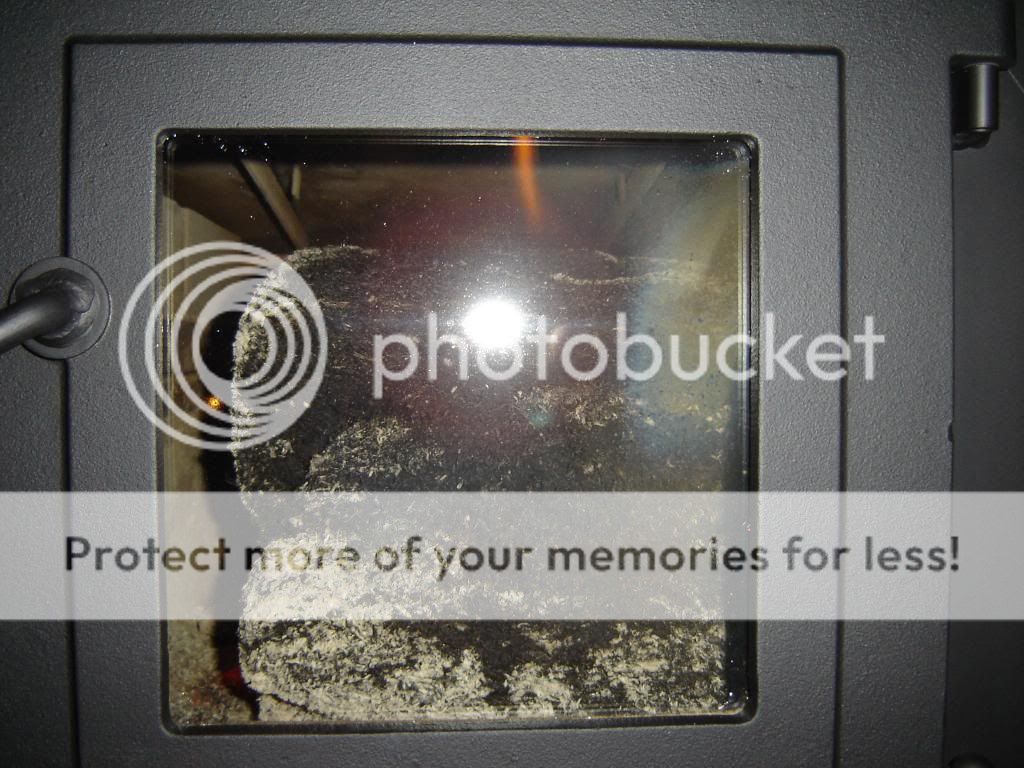

Made in good old Virginia USA. England stove works 28-3500 wood furnace from Home Depot, complete with 10% Veteran discount.

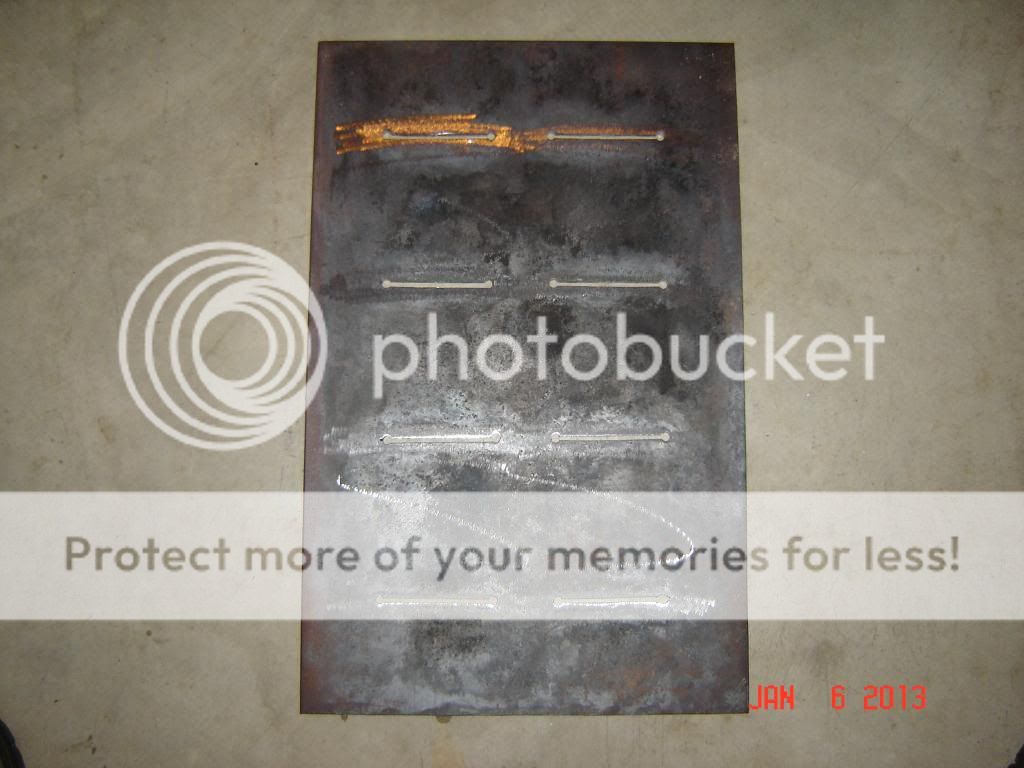

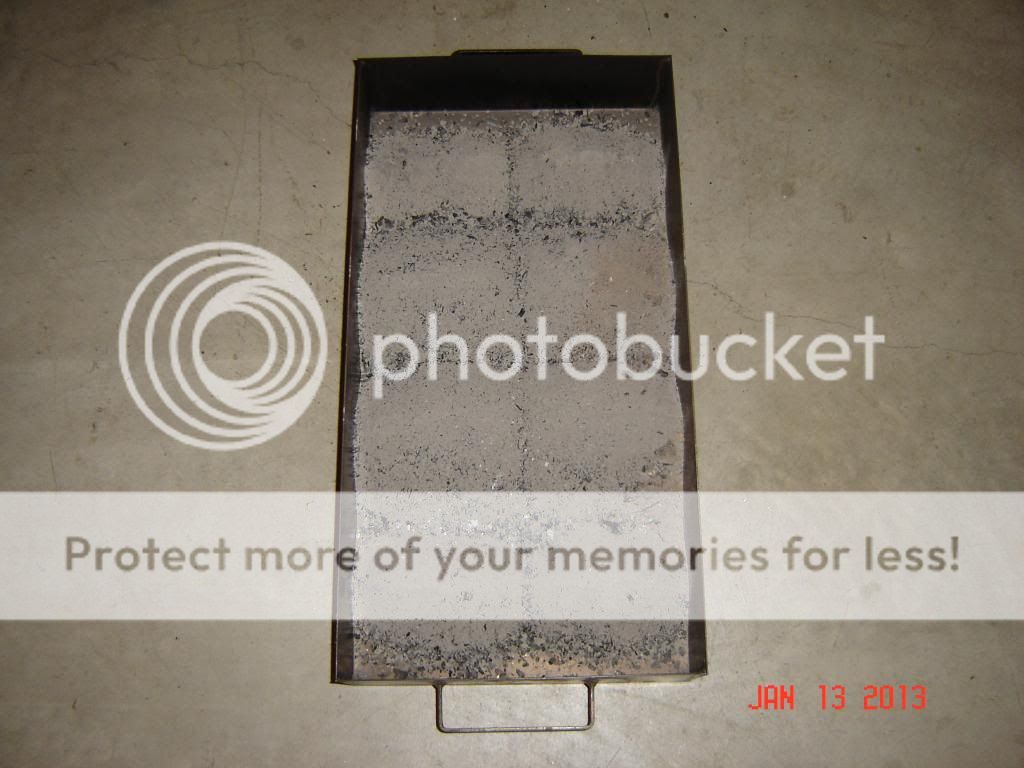

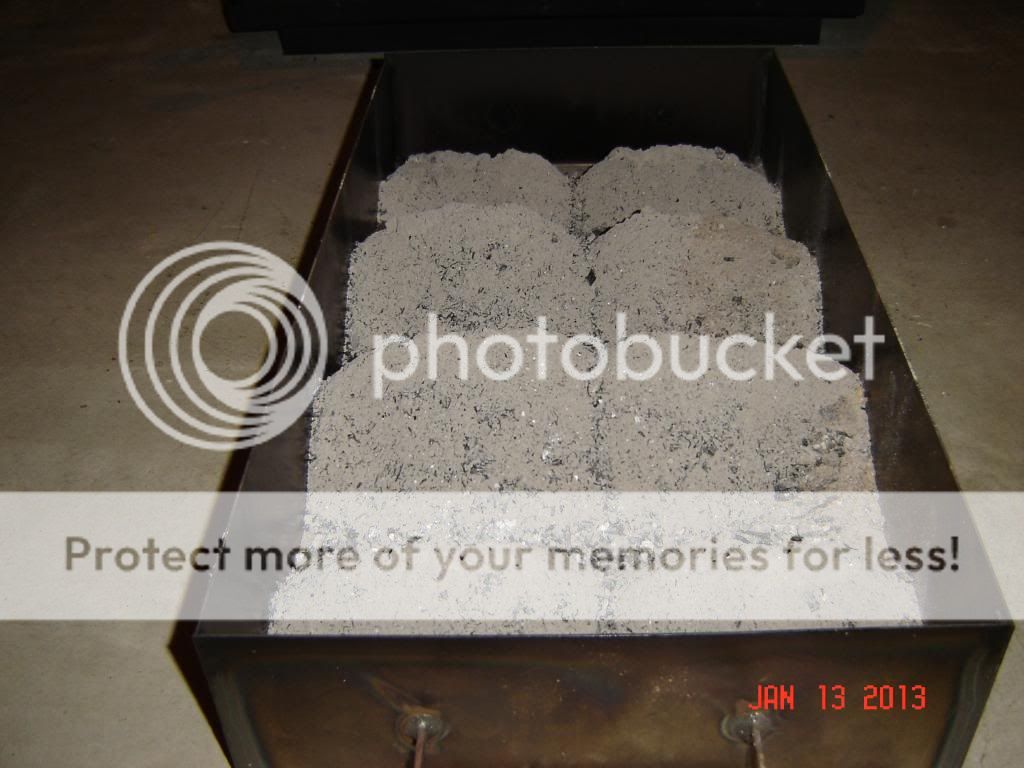

This thing is 570 lbs of 1/4" steel and has many great reviews, most of which I learned about here on Hearth.com.

After they set it in the bed of the D-max with the forklift, the young kid waving the orange flags asks me....."want some string to tie that down with?" Epic.

I've been contemplating it's replacement for nearly 2 years, finally pulled the trigger.

Made in good old Virginia USA. England stove works 28-3500 wood furnace from Home Depot, complete with 10% Veteran discount.

This thing is 570 lbs of 1/4" steel and has many great reviews, most of which I learned about here on Hearth.com.

After they set it in the bed of the D-max with the forklift, the young kid waving the orange flags asks me....."want some string to tie that down with?" Epic.

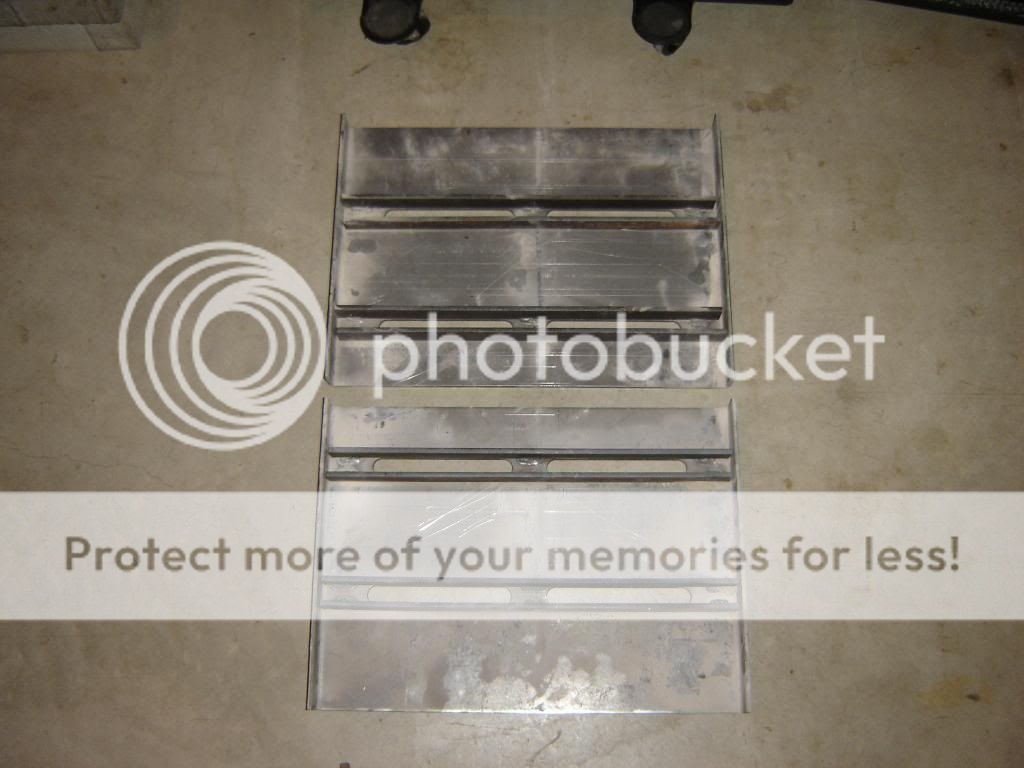

I only paid $300 for mine (used) but I had to disassemble the entire thing, lug it out of a basement up a steep staircase and out of some Bilco doors, then get it up my back steps to the kitchen, through there to the basement on a handtruck. There was a point when there was 450+ lbs of stove, a 215lb me, and a 190lb buddy all on my basement steps (which have no center stringer)-needless to say we were a little nervous, but all turned out well. Seriously, hook up some ductwork to that puppy and get heat to the entire house-it'll make a huge difference. I have mine piped directly into the plenum of my oil furnace. Got a fillup today for the first time since the end of last winter-45 gallons

I only paid $300 for mine (used) but I had to disassemble the entire thing, lug it out of a basement up a steep staircase and out of some Bilco doors, then get it up my back steps to the kitchen, through there to the basement on a handtruck. There was a point when there was 450+ lbs of stove, a 215lb me, and a 190lb buddy all on my basement steps (which have no center stringer)-needless to say we were a little nervous, but all turned out well. Seriously, hook up some ductwork to that puppy and get heat to the entire house-it'll make a huge difference. I have mine piped directly into the plenum of my oil furnace. Got a fillup today for the first time since the end of last winter-45 gallons