NE Wood Burner:

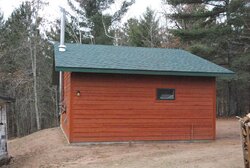

Some thoughts for your step 3. I'm hoping to be up and running for 2013/2014 and have been pulling the pieces together for a while now. These were my considerations for the Garn Barn:

20'x30' floating slab with 9' interior height. 12" of concrete with bars 12" OC both ways. Consider you have the equivelent weight of about 15 cars sitting in a 3 car garage here when the boiler and wood storage areas are full. Better safe than sorry on concrete thickness (also consider I was sitting on abut 4 foot of fresh (compacted) fill at one end). If you consider thickening just the perimiter and any other load bearing areas - note that you can thicken the whole darn slab for about the same bucks as the hand work that would entail. I considered forming a 12" high curb wall around the slab to let me use standard 8' studs and sheeting, but just decided to frame it 9' off the slab. Also consider you may want to swap out the boiler some day. The interior wall between the Boiler Room and the interior wood storage area is not load bearing to allow it's removal to move a boiler thru the overhead door in 20 or 30 years.

The odd framing direction to allow for a gable roof vent system (vs ridge or cans) to better avoid any sparkies getting into the attic.

The interior wood storage area is just covered with 3/4" CDX and the outside wall I will stack against is T1-11. No sense in tearing up good siding or wall coverings.

This is mostly a 3-stall garage with one being a car-port (2nd year wood drying) and the others being a Boiler Room and also an enclosed, mostly heated under-roof spot for 3rd year wood drying and burning (1st year cut and split is just out in the elements) Both interior stalls are fully insulated and seperated with a door between. This would allow closing down the interior wood storage, area and just heating just the boiler room if I headed south for a bit of sunshine or salt water. The boiler room will have a couple baseboard electric units to keep anything from freezing and seemed like a better idea than the Garn heating elements. During normal times - I expect the latent heat from the boiler will keep both rooms toasty by just keeping the inside door open.

Don't be cheap on the underground. Best guess said 1 1/4 Pex,would work, but upsized to 1 1/2 and encased it in a 12" block of spray foam. Don't hesitate to ruln a few extra pvc conduits between buildings to shove things like a water line or future low voltage electric after the fact. Digging a 2nd time would suck.

Run plenty of electric capacity. My box and feed would hadle 100 amps and could be used for anythig from a welder, camping trailer or backfeeding a generator. I think I could satisfy just the Garn needs with about 30 - 40 amps.

My first thought when I bought the Garn was to place the boiler in the house basement and thus why the rear exhaust. Those in the know talked me into going outdoors with it and I'm now very comfortable with that decision. A top exit exhaust would be a consideration if I was going with a seperate building from the start......but remember that forces you on the roof to clean the flue once or twice a year. Like all things..... a trade off.

I plan to get the "Pro from Dover" (Heaterman) in for a couple days in the fall to get this all up and running. I understand most construction, but am pretty clueless about details of

designing hvac.

Good Luck and don't hesitate to give me a shout if you have any questions.........remember it's more than a destination.........it's one hell of a ride!

Eauzone Dan