Woody mustash

- Thread starter mustash29

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

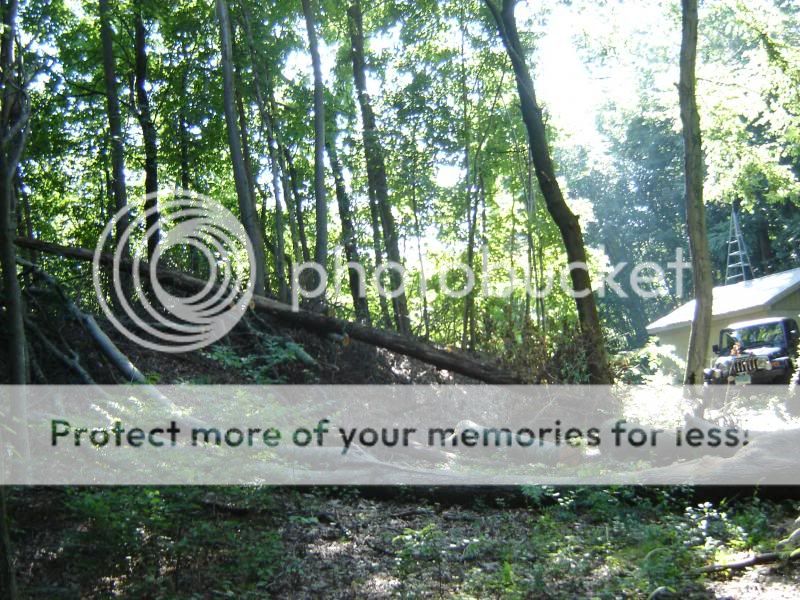

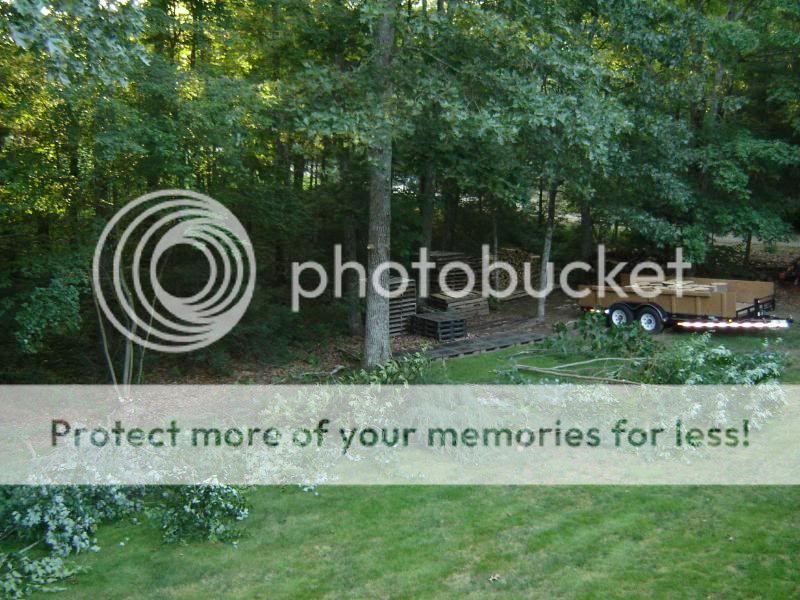

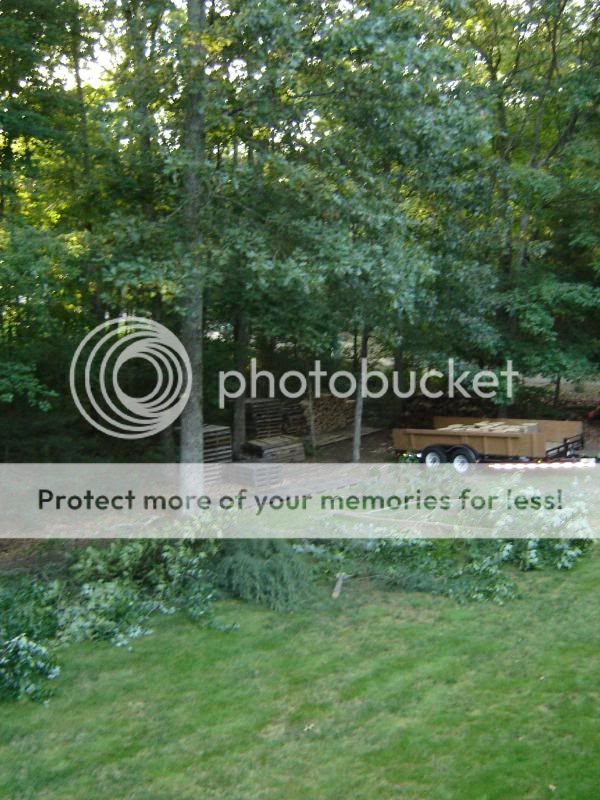

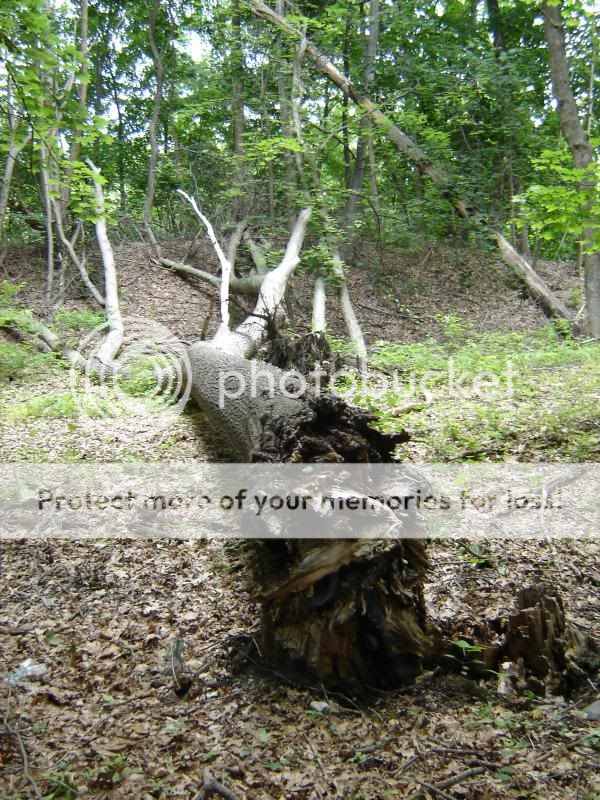

Today we worked on a new score. My work has a remote pump house, 4 shallow wells drilled near a river bank. It looks like a bomb went off down there, blowdowns gallore thanks to Irene, Sandy and a few other lesser storms we have had. My manager gave me permission to beging cleaning up the mess because we need to clear the access to the well heads just in case.

Allmost took out the gate:

Allmost took out the gate:

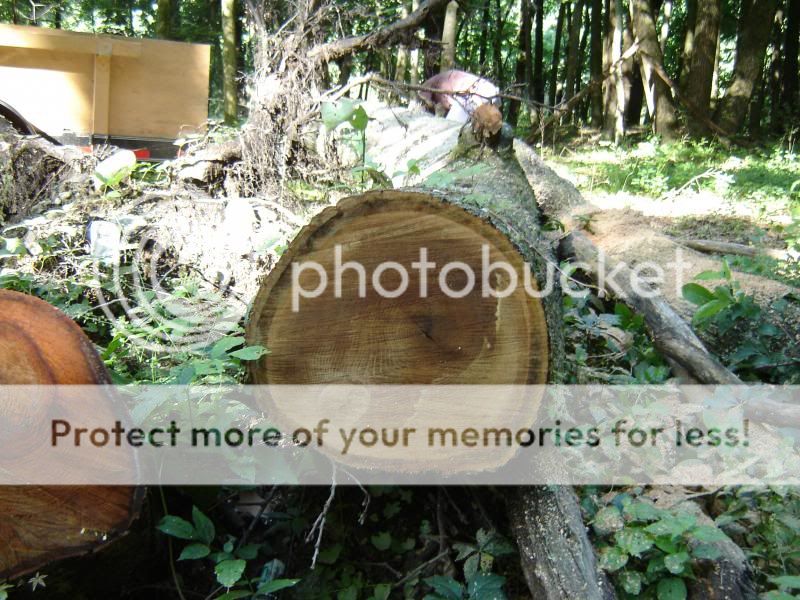

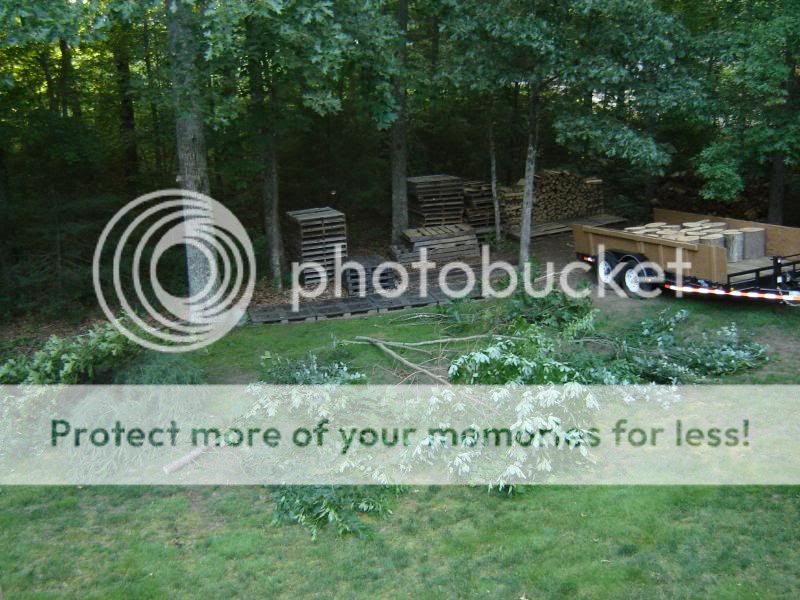

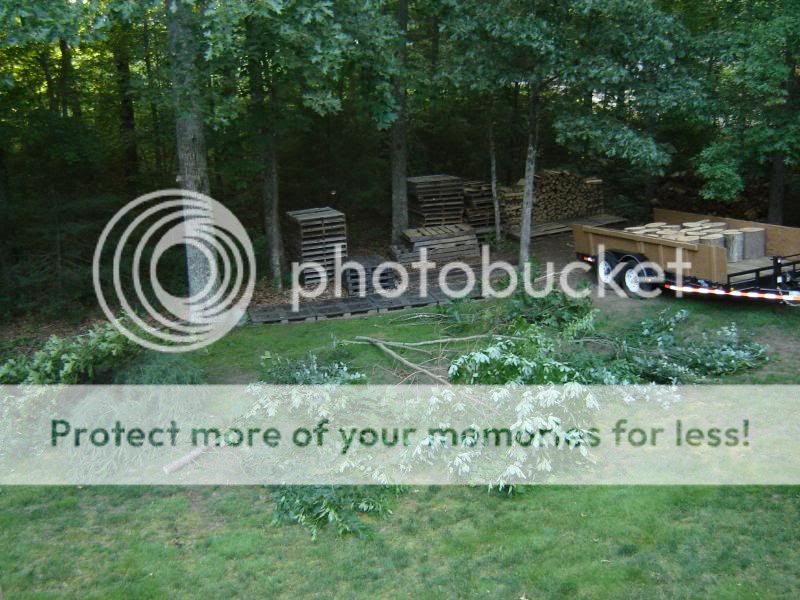

We filled the truck with some smaller top wood then had lunch at my work. The DOT scales said we had 2000 in the bed. That red oak is HEAVY.

After lunch we rolled the big ones up the trailer ramp. We had to center them over the axels due to having more in the bed than I thought.

The truck is 7000, the trailer is 2500 (14 K GVWR).

Not a bad days work. 6500 lb of mostly red oak. All the small stuff is split & stacked, just have to roll the big-uns off the trailer and onto the splitter table,

After lunch we rolled the big ones up the trailer ramp. We had to center them over the axels due to having more in the bed than I thought.

The truck is 7000, the trailer is 2500 (14 K GVWR).

Not a bad days work. 6500 lb of mostly red oak. All the small stuff is split & stacked, just have to roll the big-uns off the trailer and onto the splitter table,

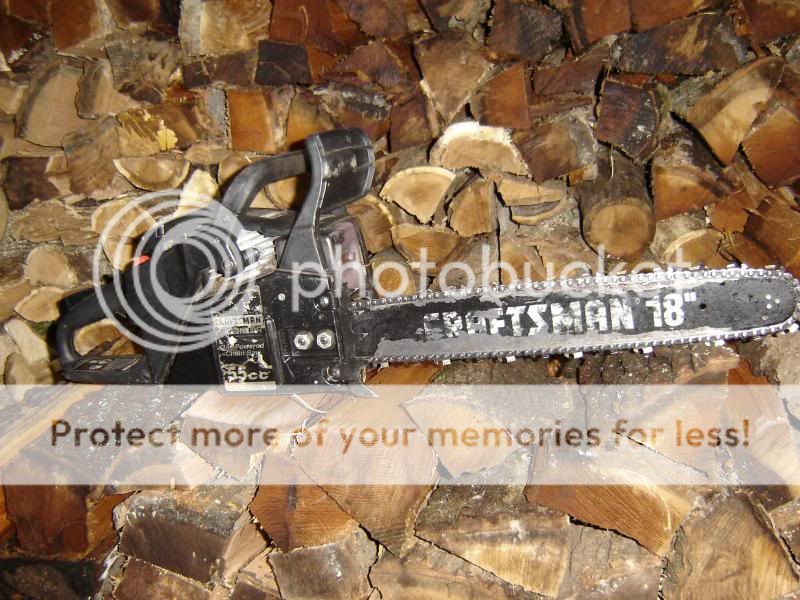

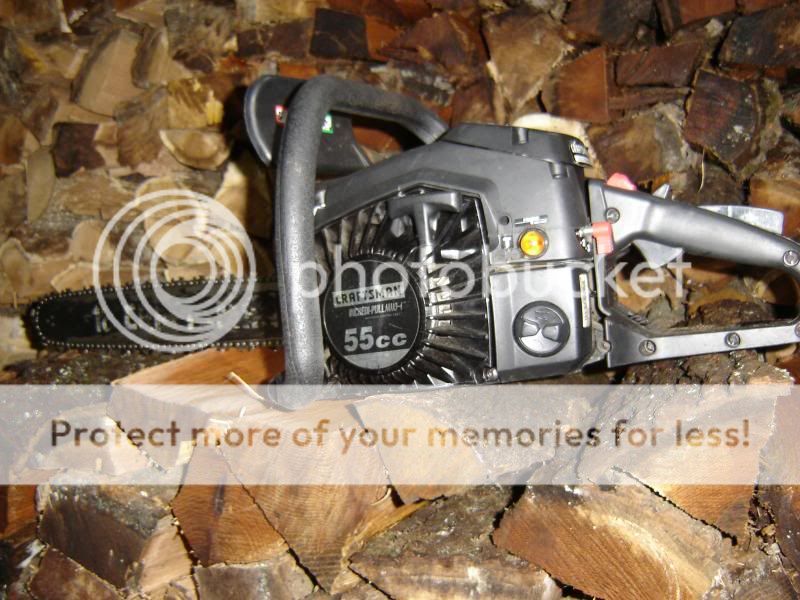

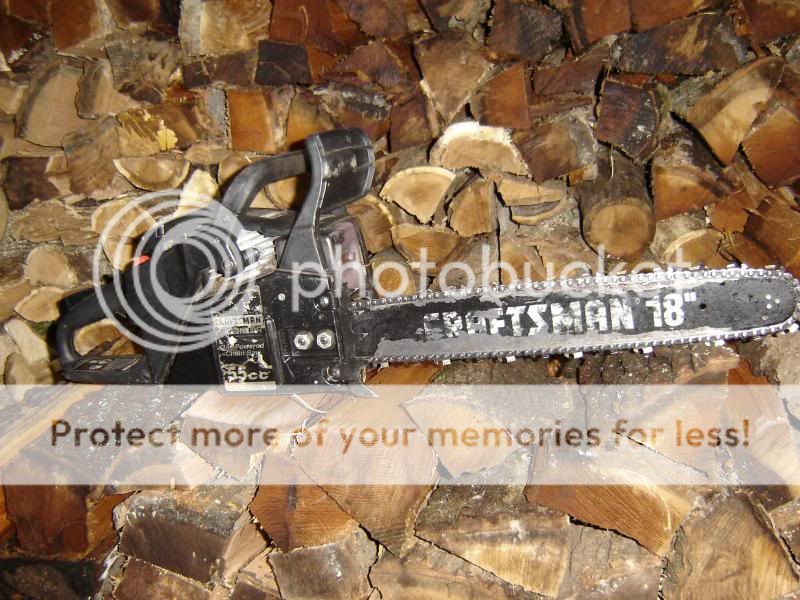

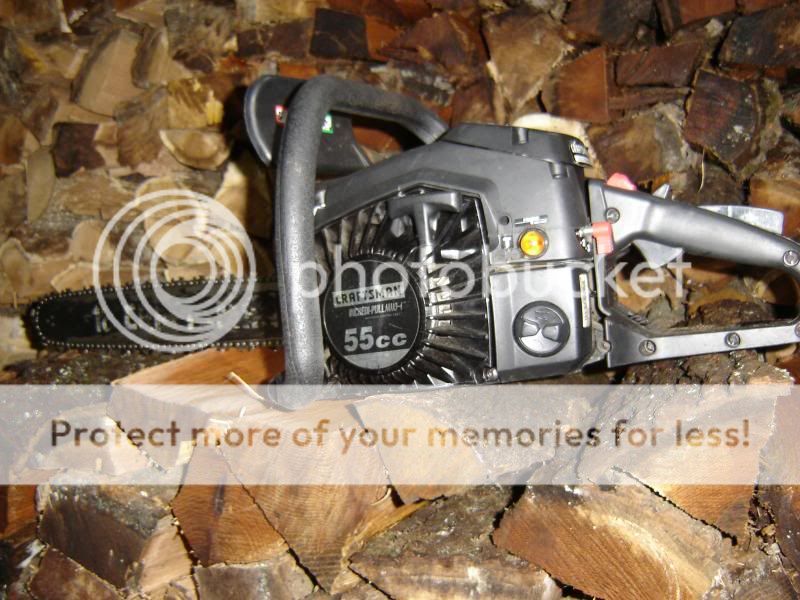

After doing the limby top stuff with a professionally re-sharpened "homeowner" (POS) Oregon chain I swapped on a brand new Stihl full chisel chain. Holy freaking cow batman, that thing RIPS. The saw is an 18" 55 cc Craftsman / Remington pro running 93 octane and Polaris full synthetic sled oil. It smells purdy.

bogydave

Minister of Fire

Impressive pictures & work effort.

When all that is CSS'd, you'll be getting way ahead for sure.

Good job cutting the rounds to the same length,

Will look great stacked & seasoning

When all that is CSS'd, you'll be getting way ahead for sure.

Good job cutting the rounds to the same length,

Will look great stacked & seasoning

Backwoods Savage

Minister of Fire

After 3 nightshifts, I woke up to my neighbor banging around, then heard his saw and 32 hp tractor running the 6" chipper.

So I did a little trimming around the perimeter. I had some low hanging crap that was blocking too much sun from my piles. Tomorrow it will be gone when I get home from work. I believe an ice cold 30 pack will be in order.

So I did a little trimming around the perimeter. I had some low hanging crap that was blocking too much sun from my piles. Tomorrow it will be gone when I get home from work. I believe an ice cold 30 pack will be in order.

northwinds

Minister of Fire

Exposure to sun and wind does make a difference in seasoning times. Great pics and thread.

Paulywalnut

Minister of Fire

firefighterjake

Minister of Fire

After doing the limby top stuff with a professionally re-sharpened "homeowner" (POS) Oregon chain I swapped on a brand new Stihl full chisel chain. Holy freaking cow batman, that thing RIPS. The saw is an 18" 55 cc Craftsman / Remington pro running 93 octane and Polaris full synthetic sled oil. It smells purdy.

Love the smell of that Polaris full synthetic sled oil . . . smells like bubble gum to me . . . when my brother-in-law was running with it (before he got a Yamaha four stroker) I could often gauge about how far behind him I was in the woods by how strong the smell was . . .

S

ScotO

Guest

All the way around GOOD STUFF here brother......

Keep up with what you are doing, you're heading in the right direction.....the path to woodburning elan......

Keep up with what you are doing, you're heading in the right direction.....the path to woodburning elan......

M

MasterMech

Guest

I'm at about 6 cords now. Just finished a little cutting and splitting. My other half is falling behind, she has about a cord to stack.

I gave the tractor and splitter a quick rinse and blew the saw off, can't post dirty pics.....

21 hp crapper, custom trailer hitch welded to the bagger mount & the MTD 31 ton with 8 hp Briggs I/C & table extension wings. When I split the big stuff right off the truck or trailer, I remove the left wing and attach a 4 foot 2x10 ramp.

And the 55 cc Craftsman / Remington Pro with Stihl full chisel:

I gave the tractor and splitter a quick rinse and blew the saw off, can't post dirty pics.....

21 hp crapper, custom trailer hitch welded to the bagger mount & the MTD 31 ton with 8 hp Briggs I/C & table extension wings. When I split the big stuff right off the truck or trailer, I remove the left wing and attach a 4 foot 2x10 ramp.

And the 55 cc Craftsman / Remington Pro with Stihl full chisel:

Spent about 3 hrs working on the larger stick yesterday, it's 24" in the middle, so about 27" at the base. I got 15 rounds pre-cut to a depth of 18", blocked it off the ground with some small rounds, 2 new felling wedges came in mighty handy, etc.

After re-fueling the saw for the third time she refused to re-start. Talk about getting PO-ed. We only netted 4 rounds, 20 x 24. I dropped the saw at the shop on the way home to have it gone through. If it's toast he said he'd waive the $40 diagnostic fee if I go with a Stihl. Seroiusly contemplating that move. This thing sometimes starts right up, but sometimes it's a tempermental POS.

After re-fueling the saw for the third time she refused to re-start. Talk about getting PO-ed. We only netted 4 rounds, 20 x 24. I dropped the saw at the shop on the way home to have it gone through. If it's toast he said he'd waive the $40 diagnostic fee if I go with a Stihl. Seroiusly contemplating that move. This thing sometimes starts right up, but sometimes it's a tempermental POS.

thewoodlands

Minister of Fire

R. I. P. I killed it.

I was hoping for a carb cleaning or something, but it is worse. Saw shop took a look at it for me, found the flywheel had come in contact with the ignition coil, ground a good 1/8" off the coil, so it has no spark. Needs $70 in parts. I should have looked into it myself, could have saved 40 bucks.....

The good news is that he had a nearly complete parts saw with bar & cheap chain (scored piston & cylinder, only 30 psi compression, missing 1/2 of the muffler, missing air cleaner & top cover). I picked that up for 10 bucks, hoping for a miracle.

I tore into mine and found the cause. One of the mount studs for the ignition coil sits on this blob, which is cracked and wiggles around. That is what allowed the coil to float around and hit the flywheel. This must have been going on for some time. Sometimes it would start right up and sometimes it would simply piss me off. The saw was lightly used, maybe cut 10 or 12 cord with it but it is 7 yrs old.

I know I will eventually wind up with a good saw, shop recommended either a Stihl MS 250 or 290 Farm Boss.

But I have it in my head I am going to make this thing run again, maybe for short term use, maybe fix it and sell it. I now have: 3 bars, 4 homeowner chains (3 sharp, 1 from parts saw) and 2 Stihl full chisel chains (1 barely used, 1 new in box) and a storage case.

I was hoping for a carb cleaning or something, but it is worse. Saw shop took a look at it for me, found the flywheel had come in contact with the ignition coil, ground a good 1/8" off the coil, so it has no spark. Needs $70 in parts. I should have looked into it myself, could have saved 40 bucks.....

The good news is that he had a nearly complete parts saw with bar & cheap chain (scored piston & cylinder, only 30 psi compression, missing 1/2 of the muffler, missing air cleaner & top cover). I picked that up for 10 bucks, hoping for a miracle.

I tore into mine and found the cause. One of the mount studs for the ignition coil sits on this blob, which is cracked and wiggles around. That is what allowed the coil to float around and hit the flywheel. This must have been going on for some time. Sometimes it would start right up and sometimes it would simply piss me off. The saw was lightly used, maybe cut 10 or 12 cord with it but it is 7 yrs old.

I know I will eventually wind up with a good saw, shop recommended either a Stihl MS 250 or 290 Farm Boss.

But I have it in my head I am going to make this thing run again, maybe for short term use, maybe fix it and sell it. I now have: 3 bars, 4 homeowner chains (3 sharp, 1 from parts saw) and 2 Stihl full chisel chains (1 barely used, 1 new in box) and a storage case.

I'm thinking a large blob of high temp epoxy may beef that area up so that it can accept the used coil and flywheel? Temp and vibrations would be my concern for longevity.

I already have some Permatex # 765-1248 liquid metal epoxy on hand. I used that to repair her Focus. I did the timing belt job on it and stripped the threads out of 1 of the 4 holes that holds the water pump into the alumnium block. This stuff cures so hard it requires a file or grinding wheel to sand it down.

Adheres to alumnium, iron, steel, brass, magnesium, copper. Resistant to most solvents, oil, motor oil, glycol, diesel, not for use with brake fluid.

Temp range -65 to 300, intermittent to 350.

Any other high heat epoxy out there?

The other option would be to have my buddy at work do a little alumnium welding project for me.

I already have some Permatex # 765-1248 liquid metal epoxy on hand. I used that to repair her Focus. I did the timing belt job on it and stripped the threads out of 1 of the 4 holes that holds the water pump into the alumnium block. This stuff cures so hard it requires a file or grinding wheel to sand it down.

Adheres to alumnium, iron, steel, brass, magnesium, copper. Resistant to most solvents, oil, motor oil, glycol, diesel, not for use with brake fluid.

Temp range -65 to 300, intermittent to 350.

Any other high heat epoxy out there?

The other option would be to have my buddy at work do a little alumnium welding project for me.

Blue2ndaries

Minister of Fire

Man you've been cranking Awesome work and even more awesome set-up---yard, trailer, stacks, truck....

Awesome work and even more awesome set-up---yard, trailer, stacks, truck....

Awesome work and even more awesome set-up---yard, trailer, stacks, truck....

Awesome work and even more awesome set-up---yard, trailer, stacks, truck....Ashful

Minister of Fire

Yeah... what gives?!? No mustache.

No advice on the saw, other than you won't regret buying a Stihl. Before buying one new from the local Stihl shop, I'd PM member DexterDay to see what he has to offer. Another new member, Big Donnie Brasco, can give you a reference on his work.

No advice on the saw, other than you won't regret buying a Stihl. Before buying one new from the local Stihl shop, I'd PM member DexterDay to see what he has to offer. Another new member, Big Donnie Brasco, can give you a reference on his work.

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 3

- Views

- 1K

- Replies

- 2

- Views

- 551

- Replies

- 15

- Views

- 4K

It was just limb stuff though and it was under a lot of tension the way it fell.

It was just limb stuff though and it was under a lot of tension the way it fell.