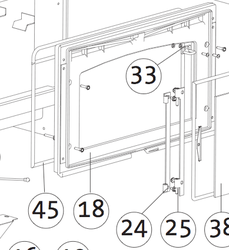

Attached are two pictures of my Jotul insert. It was installed last summer by a professional stove dealer along with a liner. I started running it in October and have been using it on and off (mostly on) since then. I've burned about three cords I'd guess. Tonight my wife noticed the two cracks shown in the pictures. After I thought about it I did hear it making some noises last night as it was cooling down, but I thought it was just the usual "pinging" type of noises that happen when it is heating or cooling.

I've always used a stove thermometer from the very first time I ran it, so I know that it has never gotten extremely hot. 99.9% of the time it has run between 400-600 degrees. Once or twice with some very dry wood back in November it got up to 700-800 or so before cooling down to normal but it has been quite a while since it got that hot (and I didn't even think that should have been a problem).

I just noticed it tonight so I haven't talked to anyone yet. (Right now my last fire is dying down.) I assume it is still covered under warranty since I've only had it since last July. So, I'm curious: (1) has anyone else had/seen this on the Jotul insert or any other cast iron stove, and (2) any thoughts on what I should expect the dealer/Jotul to do to rectify this?

Thanks.

I've always used a stove thermometer from the very first time I ran it, so I know that it has never gotten extremely hot. 99.9% of the time it has run between 400-600 degrees. Once or twice with some very dry wood back in November it got up to 700-800 or so before cooling down to normal but it has been quite a while since it got that hot (and I didn't even think that should have been a problem).

I just noticed it tonight so I haven't talked to anyone yet. (Right now my last fire is dying down.) I assume it is still covered under warranty since I've only had it since last July. So, I'm curious: (1) has anyone else had/seen this on the Jotul insert or any other cast iron stove, and (2) any thoughts on what I should expect the dealer/Jotul to do to rectify this?

Thanks.