A few months back I posted a thread about buying a splitter for the camp I work at with money that was donated. Well, here is the current situation: we will be keeping the existing splitter on site, and have $2000 of donated money to put towards a new splitter. the camp itself can pitch in some more money if need be.

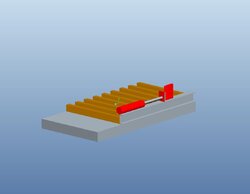

i have not really found anything on the market that i am in love with and started to consider building something myself. I have a large trailer that i plan to turn into a wood processing center. off of the one side of the trailer i plan to attach a log lifter. the trailer will have a platform that we can also set full length logs onto and buck right in place. on the opposite side of the trailer i plan to mount the splitter itself.

the questions i have for you experts is in reference to the spec i should design the splitter around. this will pretty much always be operated when we have a group of 4 to 8 people present. i want it to be safe, but i also want it to be able to keep up with that amount of manpower. my thought is we would have a couple people supplying the logs, a couple people working the splitter end, and 2-4 stacking.

what would your suggestions be for engine size, pump size, cylinder size, etc.

thanks for any suggestions.

i have not really found anything on the market that i am in love with and started to consider building something myself. I have a large trailer that i plan to turn into a wood processing center. off of the one side of the trailer i plan to attach a log lifter. the trailer will have a platform that we can also set full length logs onto and buck right in place. on the opposite side of the trailer i plan to mount the splitter itself.

the questions i have for you experts is in reference to the spec i should design the splitter around. this will pretty much always be operated when we have a group of 4 to 8 people present. i want it to be safe, but i also want it to be able to keep up with that amount of manpower. my thought is we would have a couple people supplying the logs, a couple people working the splitter end, and 2-4 stacking.

what would your suggestions be for engine size, pump size, cylinder size, etc.

thanks for any suggestions.