I live in a part of the Pacific Northwest that gets 60+ inches of rain a year and also sees some occasional high winds. In my early wood burning days, I tried covering my wood pile with tarps but they quickly developed holes and seemed to trap more water than they kept out!

Last year I covered my wood pile with plywood and that worked a little better, but it was quite a chore to get wood from the pile. I only have a little space in the garage to hold wood for current season burning, so I had to wrestle the plywood several times during the winter to replenish my burn pile.

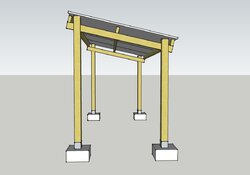

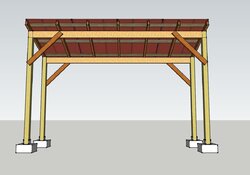

I had hoped to built a proper wood shed this summer, but simply ran out of time. So now I have scaled back my goals and just want to build a port around the existing wood pile. Since this is intended to be a temporary solution (1-2 seasons only), I would like to use 2x4 lumber and a few post bases that I have laying around. My main investment would be some 3'x5' metal roofing panels that I found on Craig's List.

So, with that long introduction, here are my questions:

- will the structure in the attached drawing work if built with 2x4 lumber (rather than having to buy bigger dimensional lumber?)

- the port would be 11' or 12' long and 4' deep, but how high should I make it?

- if the roof cross-beams are 2' on center then the metal sheets will have 6" unsupported on either end -- is that a problem?

- do you think this structure will be solid enough to withstand 50 mph gusts?

- any other construction suggestions?

Thanks, as always, for sharing your hard earned wisdom!

Last year I covered my wood pile with plywood and that worked a little better, but it was quite a chore to get wood from the pile. I only have a little space in the garage to hold wood for current season burning, so I had to wrestle the plywood several times during the winter to replenish my burn pile.

I had hoped to built a proper wood shed this summer, but simply ran out of time. So now I have scaled back my goals and just want to build a port around the existing wood pile. Since this is intended to be a temporary solution (1-2 seasons only), I would like to use 2x4 lumber and a few post bases that I have laying around. My main investment would be some 3'x5' metal roofing panels that I found on Craig's List.

So, with that long introduction, here are my questions:

- will the structure in the attached drawing work if built with 2x4 lumber (rather than having to buy bigger dimensional lumber?)

- the port would be 11' or 12' long and 4' deep, but how high should I make it?

- if the roof cross-beams are 2' on center then the metal sheets will have 6" unsupported on either end -- is that a problem?

- do you think this structure will be solid enough to withstand 50 mph gusts?

- any other construction suggestions?

Thanks, as always, for sharing your hard earned wisdom!