Thanks for taking the time to read this. I know I get long winded, but I want your opinion and you can’t give me an honest one without all the facts.

We currently use LP as our main source of heat, and the price has skyrocketed in recent years. I live on a farm, and we have plenty of fence rows with green lumber, not to mention, wild woods. Seems logical to grow my own heat, rather than pay for some dead dinosaurs.

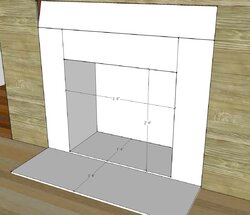

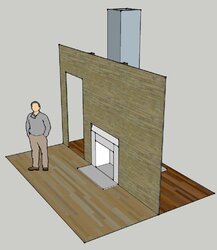

I’m thinking of resurrecting an old chimney in a ca. 1920 farmhouse. The top of the chimney was taken down recently when a metal roof was installed. Most of the mortar (what looks like sandy clay) had washed out, anyway. The mortar still looks solid on the parts that were inside the roof. It is a double fireplace, the East smoke chamber opening was sealed up, when a set of vent free gas logs were installed. I want to use the West facing fireplace to install an insert to be the main heat in the house. The fireplace opening is 28” High, 33” Wide, and 16” Deep. The hearth is 16” deep, 48” Wide, and 1” above the linoleum. The flue is 12” square. The firebox sidewalls appear to be 8” thick, while the flue walls are 4”. The whole chimney and hearth is sitting on a pillar of dirt built up from the ground.

For the longest time I thought the whole chimney was a write off, but then I stumbled across UL 103-HT metal chimneys and insulated stainless flue liner. I now wonder if it could be made safe to operate.

My first idea was to remove the flue bricks (unlined chimney) and attach the metal chimney to the smoke chamber, then use an insulated flexible liner to attach to an insert. Then I found that at Rockford, Class A HT chimney, at $3.58/in., is more expensive than SS 316 insulated liner, at $2.56/in.

My next idea, then, was to use an insulated, smooth wall, flexible liner up to the top of the existing chimney, then finish with Class A HT chimney. I was looking for metal prices at Lowes to make a block off plate, when I saw that they had their SuperVent chimney parts on clearance for $65/36”, or $1.81/in. This stuff is made by Selkirk and, from what I can find, has the same warranty, and is made of the same materials, as their MetalBest line.

So now the plan is to use as much Class A as I can, and finishing up with a piece of insulated flexible lining.

If you've made it this far, could I now ask some questions? Other than these two?

Does this sound like a safe thing to do, or would you rather tear the whole thing down and rebuild to modern code?

I’m a handy man, and like to keep costs down by doing most work myself. (Also, I’m too cheap to pay for something I can do myself.) That said, is it safe for me to install this stuff myself? It looks easy to me, but looks are sometimes deceiving.

Barring the fire losing containment, how hot can I expect the outside of the chimney to get if the insert is used 24/7? Will most of the heat in a modern insert be directed out the front? My current favorite insert is 27” wide, which will leave a 3” air gap. The reason I ask, is that there are some wooden beams touching the masonry on the corners at the opening, and I don’t want to be unsafe. This is a loadbearing wall, so I don’t want to touch them. Anyway, I can’t access the one on the left without removing either the chimney or the wooden wall.

If this looks like it will pan out, I’ll post some more questions, but they’re moot if I can’t do this myself.

We currently use LP as our main source of heat, and the price has skyrocketed in recent years. I live on a farm, and we have plenty of fence rows with green lumber, not to mention, wild woods. Seems logical to grow my own heat, rather than pay for some dead dinosaurs.

I’m thinking of resurrecting an old chimney in a ca. 1920 farmhouse. The top of the chimney was taken down recently when a metal roof was installed. Most of the mortar (what looks like sandy clay) had washed out, anyway. The mortar still looks solid on the parts that were inside the roof. It is a double fireplace, the East smoke chamber opening was sealed up, when a set of vent free gas logs were installed. I want to use the West facing fireplace to install an insert to be the main heat in the house. The fireplace opening is 28” High, 33” Wide, and 16” Deep. The hearth is 16” deep, 48” Wide, and 1” above the linoleum. The flue is 12” square. The firebox sidewalls appear to be 8” thick, while the flue walls are 4”. The whole chimney and hearth is sitting on a pillar of dirt built up from the ground.

For the longest time I thought the whole chimney was a write off, but then I stumbled across UL 103-HT metal chimneys and insulated stainless flue liner. I now wonder if it could be made safe to operate.

My first idea was to remove the flue bricks (unlined chimney) and attach the metal chimney to the smoke chamber, then use an insulated flexible liner to attach to an insert. Then I found that at Rockford, Class A HT chimney, at $3.58/in., is more expensive than SS 316 insulated liner, at $2.56/in.

My next idea, then, was to use an insulated, smooth wall, flexible liner up to the top of the existing chimney, then finish with Class A HT chimney. I was looking for metal prices at Lowes to make a block off plate, when I saw that they had their SuperVent chimney parts on clearance for $65/36”, or $1.81/in. This stuff is made by Selkirk and, from what I can find, has the same warranty, and is made of the same materials, as their MetalBest line.

So now the plan is to use as much Class A as I can, and finishing up with a piece of insulated flexible lining.

If you've made it this far, could I now ask some questions? Other than these two?

Does this sound like a safe thing to do, or would you rather tear the whole thing down and rebuild to modern code?

I’m a handy man, and like to keep costs down by doing most work myself. (Also, I’m too cheap to pay for something I can do myself.) That said, is it safe for me to install this stuff myself? It looks easy to me, but looks are sometimes deceiving.

Barring the fire losing containment, how hot can I expect the outside of the chimney to get if the insert is used 24/7? Will most of the heat in a modern insert be directed out the front? My current favorite insert is 27” wide, which will leave a 3” air gap. The reason I ask, is that there are some wooden beams touching the masonry on the corners at the opening, and I don’t want to be unsafe. This is a loadbearing wall, so I don’t want to touch them. Anyway, I can’t access the one on the left without removing either the chimney or the wooden wall.

If this looks like it will pan out, I’ll post some more questions, but they’re moot if I can’t do this myself.