A few of you may remember some FLIR thermal images I posted of my house, showing very clearly the location of each stove within. If not, here's the pertinent post, quoted below:

Well, I obtained some 22" x 24" heavy steel (looks to be 0.050"ish) panels for rear heat shields, and I have a sheet metal shop bending up more of the same material for lintel shields (safety first!). The material is something the sheet metal shop had laying in their bins from an old job, so it does need some cleaning up, prior to painting.

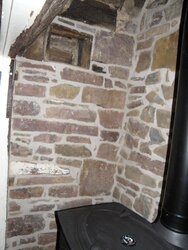

My current plan is to drop all four shields off at a local sandblasting shop, who've done a good bit of work for me on prior projects, and then prime/paint them black or dark gray after the sandblasting. Installed locations to be these two stone fireplaces, which everyone has probably already seen too many times:

Best thing to paint them with? I was thinking black metallic stove brite (would match the one re-painted Jotul), but I'd be interested in knowing if Stove Brite is the best thing to use, and if there might be a better color to blend in. You will see the bottom 1" of the lintel shield, all the way across the opening. The rear shield won't be visible when viewing straight-on, but you will see it from any angle other than straight-on.

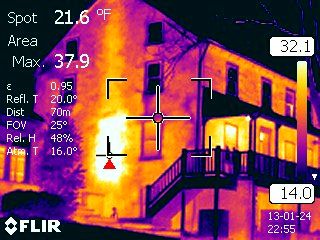

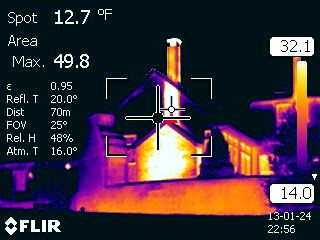

These are the two photos of most interest to me:

The stove which is much closer (3") to the stone wall reads only 38F on the outside of the wall, whereas the stove that's much further (12") from the stone wall reads 49F on the outside. I guess the big wall is a decent heat sink, on a night when it's 16F outside.

I'm wondering if it's worth playing with some shielding between the stove and wall. Not much room there on the new install, and I fear a user-designed shield placed that close to the rear of the stove may inadvertently cause damage to the stove, by trapping and reflecting more heat at the back than the designer ever intended. Sure would be nice to limit what heat I'm contributing to the great outdoors, though.

Well, I obtained some 22" x 24" heavy steel (looks to be 0.050"ish) panels for rear heat shields, and I have a sheet metal shop bending up more of the same material for lintel shields (safety first!). The material is something the sheet metal shop had laying in their bins from an old job, so it does need some cleaning up, prior to painting.

My current plan is to drop all four shields off at a local sandblasting shop, who've done a good bit of work for me on prior projects, and then prime/paint them black or dark gray after the sandblasting. Installed locations to be these two stone fireplaces, which everyone has probably already seen too many times:

Best thing to paint them with? I was thinking black metallic stove brite (would match the one re-painted Jotul), but I'd be interested in knowing if Stove Brite is the best thing to use, and if there might be a better color to blend in. You will see the bottom 1" of the lintel shield, all the way across the opening. The rear shield won't be visible when viewing straight-on, but you will see it from any angle other than straight-on.