Mr._Graybeard

Feeling the Heat

For comparison purposes, my boiler is direct vented, no OAK. The exhaust vent rises 5.5 feet and has a 9-foot horizontal run to the outside.

I burned about six tons last year -- four tons softwood, the rest hardwood and blends -- and maintained the stove regularly. Firepot scraped every couple days, traps cleaned every week or so, combustion fan checked and leaf blower trick about halfway through the season.

Last year we had a fairly mild fall here, which means the boiler got to cool down a bit during the day. That might mean the burnpot saw some fairly wide temperature swings, especially at the spot closest to the igniter. I have had the minimum temp dial set at 140 -- I think I'm going to raise it a bit, to 150 (max is at 160 right now). When winter really sets in I'll bump it to 180/160.

I burned about six tons last year -- four tons softwood, the rest hardwood and blends -- and maintained the stove regularly. Firepot scraped every couple days, traps cleaned every week or so, combustion fan checked and leaf blower trick about halfway through the season.

Last year we had a fairly mild fall here, which means the boiler got to cool down a bit during the day. That might mean the burnpot saw some fairly wide temperature swings, especially at the spot closest to the igniter. I have had the minimum temp dial set at 140 -- I think I'm going to raise it a bit, to 150 (max is at 160 right now). When winter really sets in I'll bump it to 180/160.

There HAS to be a common denominator.. My signature pretty much sums up my usage 7 + tons pellets from mid December to end of season. My burn pot looks un changed in any significant way. my vent goes up 5' ...90° ...then straight out 5'...most of the season OAK.. I have a pressure igniter. I'm very curious . Maybe if everyone posts their setup, it will stand out. Kevrev,, how does your setup compare to Mr. Graybeard's setup.?

There HAS to be a common denominator.. My signature pretty much sums up my usage 7 + tons pellets from mid December to end of season. My burn pot looks un changed in any significant way. my vent goes up 5' ...90° ...then straight out 5'...most of the season OAK.. I have a pressure igniter. I'm very curious . Maybe if everyone posts their setup, it will stand out. Kevrev,, how does your setup compare to Mr. Graybeard's setup.?

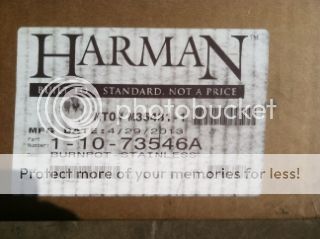

Gonna switch out my burnpot today and fix my old one. I'm very unhappy. Now my bulk feeder likes to make sawdust outa the pellets...this morning I wake up to a stove not burning...7 blinks (no such thing ...BUT I can fu%^$ing count)

Gonna switch out my burnpot today and fix my old one. I'm very unhappy. Now my bulk feeder likes to make sawdust outa the pellets...this morning I wake up to a stove not burning...7 blinks (no such thing ...BUT I can fu%^$ing count)