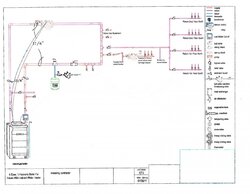

I've had my Innova connected and running happily for a few weeks now. I am having some problems with making the existing gas boiler coexist with the wood system. I've attached a schematic of what I did and what the existing setup was. I have to close the supply valve from the primary loop to prevent ghost flow from the wood system. That works fine except if I want the gas to come on. I could put a zone valve there but there isn't space to do it without making huge changes which I don't want to do at this time of the year.

My zones are piped as a secondary loop off the primary but the silly thing is that the gas boiler is in the primary loop. I had considered just using one of the tees and connecting to that gas primary loop. The pump there is a Taco 0011 which is a bit power hungry (~200 watts) which is what is discouraging me from doing that. I could do that as a short term solution until the heat is off at the end of the season.

Does anyone have suggestions about other ways to integrate the two systems? I can take some photos if that would be helpful too.

My zones are piped as a secondary loop off the primary but the silly thing is that the gas boiler is in the primary loop. I had considered just using one of the tees and connecting to that gas primary loop. The pump there is a Taco 0011 which is a bit power hungry (~200 watts) which is what is discouraging me from doing that. I could do that as a short term solution until the heat is off at the end of the season.

Does anyone have suggestions about other ways to integrate the two systems? I can take some photos if that would be helpful too.