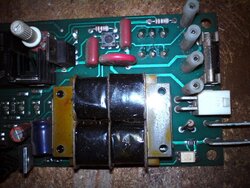

hello all, i have a whitfield advantage 2. It has no igniter system. Here is what it is doing. Upon pushing the start button the fuse blew on the control board. I replaced the fuse and pressed start again and it ran for a few minutes but the convection blower wouldnt turn. I attempted to get the motor working oiling and cleaning and it was shot. I replaced the convection blower assembly. I started the stove up and it ran for 10 minutes and the fuse blew again. The combustion blower is new as well. So i unplugged the auger motor and hand fed the stove pellets for 45 minutes finally the fuse blew again, opening and closing the door to dump pellets every few minutes. Both the combustion and convection motors turn freely. The auger motor seems to work as intended when i hook it up to 120 volt plug by itself (trying to isolate it to see if it makes any weird noise or heats up). When i vacuumed the pellets out of the hopper i did it carefully to see if there was an excess of dust or material jamming the auger. never saw a thing. I started checking all the wiring for a pinch or bare spot that might have been shorting out and it all looks to be in great condition. I took all 3 snap discs and hooked each one up to my multimeter and took a heat gun to them and they open and close as they are supposed to. can a snap disc short to the chassis upon opening or closing maybe?? The control board was put on another identical stove and it worked flawlessly for 5 hours and at that point i figured that the board was not the culprit.. This stove worked Great all last winter it burned clean, it looks pretty dirty on the glass from my pellet dumping and it smoldering out. It has been unplugged all summer until i attempted to fire it up a couple days ago. I am out of ideas. Any suggestions are appreciated ....I know i know go buy a new one....I wish...thats not an option at this point. Thank you all in advance!! here is a picture of this beast