- Sep 26, 2012

- 82

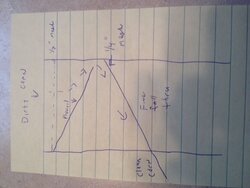

I have access to corn at a good price in bulk @ 120/ton. The problem is that some of the corn is dusty and has lots of paper like fines. I built a kan-burnbuilt out of a 4 inch drain PVC with a 45 degree 2" tee inlet that seals to the top of a 5 gallon collection bucket. The unit transfers the corn well but is not cleaning as thoroughly as I need. I am using 1/4 inch hardware cloth to stop corn from entering shop vac. I noticed a lot of static electricity in the collection bucket. I am wondering if this is causing a problem. Any suggestions to improve the design is welcomed. I will try to post some pictures when I am home later. Even after running it through several times there is still quite a bit of fines. Thanks, Matt