precaud said:

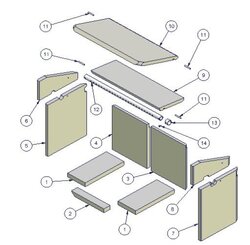

More thoughts. As you can see, the two baffles have pins which fit into holes drilled in the Skamol, the pins fit into receptacles in the stove body to hold the baffles in place. Dimensions and tolerances would have to be pretty tight on these. If the other pieces are merely cracked, you should try cementing them back together with furnace cement.

You could probably use Kaowool M-board for the two baffle pieces, since they are not subject to being banged up by wood. It is available in 1" thickness, is thermally superior to the Skamol, is fairly reasonable, and you can cut it into shapes pretty easily. The bit about the holes is an unknown, though.

I replaced the Skamol baffle in my X33 with 1" M-board and the stove definitely burns better with it in there.

Regardless, if you decide to buy the stove, definitely remove all the Skamol pieces before transporting it.

Precaud,

This post is 2 years old, but it popped up when I searched forum for Scan.

I have my Scan 60 for 4 seasons now. Great stove. It is very efficient and has unbelievable fire presentation via it's huge glass. But definitely not an all-nighter stove.

Last 3 seasons I use it as a primary heat source for my 1250 SQFT ranch.

When I did preseason clean up yesterday right small panel (#8 in your diagram) fall apart right where pin hole is.

I am thinking to use fireplace cement to 'glue' it. But I also observed cracks on a big back and left panels.

So I am wondering about your experience with M-boards as a replacement for Skamol. Or maybe you know if Skamol or Skamolex

panels are available now in US.