Jim K in PA

Minister of Fire

Brandon - Glad to hear you have found a contractor that can assist. Nothing like having eyes on the project directly to get to the right answer. Keith did respond to your email with the drawing (I spoke with him today) but perhaps it got "lost in the sauce". His advice was to find a good local contractor skilled in hydronics, which it appears you have already done.

There was a period where TWH was no longer the rep for PA, and I had not come on board yet. You did nothing wrong. I'll help as much as I can, and will at least arm you with some pointed questions for your contractor.

The GARN is a very efficient, simple device. It is also simple to connect to whatever system you want, but most of the design decisions have to be made based on the load side considerations, not the supply (GARN) side. As with any heat generation device, it converts fuel into heat, and has a supply and a return port. Beyond that the sky is the limit on how you build your system. The good news is that if you do the basics correctly (properly sized and insulated lines, etc.) you can correct any potential "mistakes" without having to touch the GARN side of the installation at all.

Jim

There was a period where TWH was no longer the rep for PA, and I had not come on board yet. You did nothing wrong. I'll help as much as I can, and will at least arm you with some pointed questions for your contractor.

The GARN is a very efficient, simple device. It is also simple to connect to whatever system you want, but most of the design decisions have to be made based on the load side considerations, not the supply (GARN) side. As with any heat generation device, it converts fuel into heat, and has a supply and a return port. Beyond that the sky is the limit on how you build your system. The good news is that if you do the basics correctly (properly sized and insulated lines, etc.) you can correct any potential "mistakes" without having to touch the GARN side of the installation at all.

Jim

Thanks everyone. I appreciate the help. Jim I will be in touch with you. I met with a heating contractor yesterday who as far as I can tell is very knowledgable. He thinks I am on the right track. I just don't want to get it up and running and not perform as expected.

The other year when I purchased it I couldn't find a rep. "This warm house". Used to be but stopped right when I went to order. If someone else was I didn't mean to cut them out.

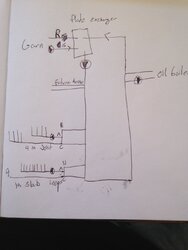

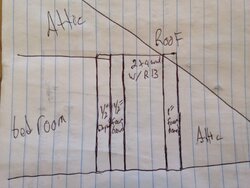

I have talked to Keith a few times. I sent him some drawings for review. I didn't hear back from him and figured he was too busy to review them.

Merry Christmas everyone.