I helped a buddy replace a run of baseboard in his basement. It was an interesting loop. The supply and the return came in through a wall from the boiler room. The supply was on the bottom and went through the fin tube. We then looped back and the return ran through the baseboard cover and back out on top of the supply. No big deal, pretty standard.

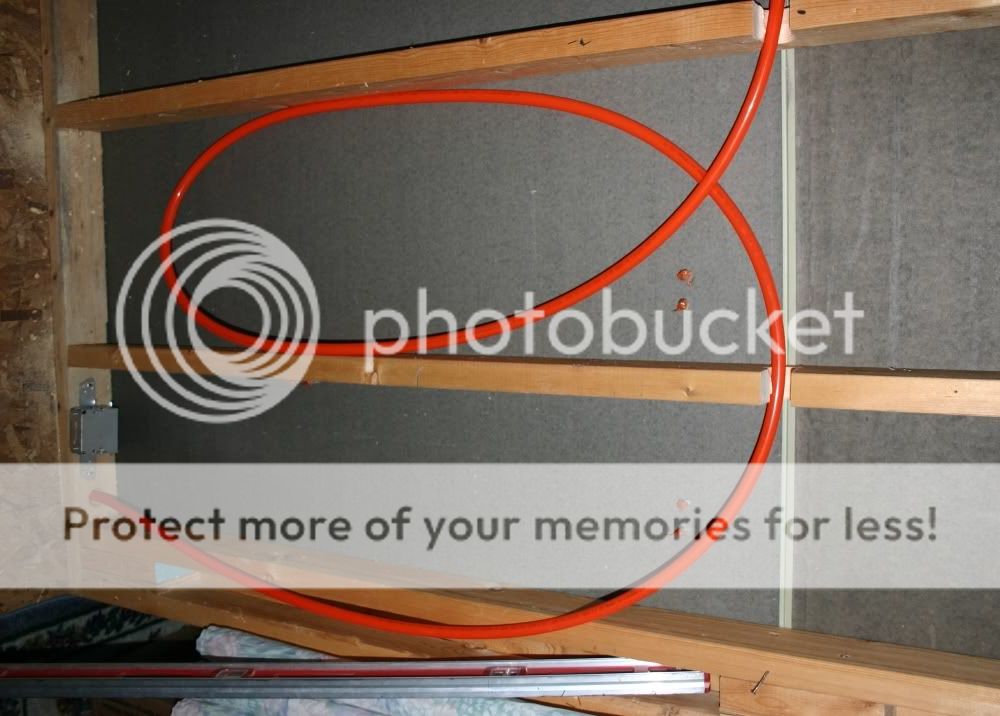

My buddy wanted to use a length of Pex for the return as it was 20' and it saved about $40 over the cost of 3/4 copper. So I cut it to length and installed it.

We fired up the zone. The moment the 190F boiler supply hit that Pex it expanded ~3" in length and wouldn't fit in the register cover any more.

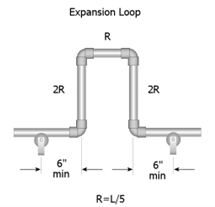

How do people work with this stuff? How do you account for 3" linear expansion on a straight 20' run?

ac

My buddy wanted to use a length of Pex for the return as it was 20' and it saved about $40 over the cost of 3/4 copper. So I cut it to length and installed it.

We fired up the zone. The moment the 190F boiler supply hit that Pex it expanded ~3" in length and wouldn't fit in the register cover any more.

How do people work with this stuff? How do you account for 3" linear expansion on a straight 20' run?

ac