I am trying to come up with a way to deal with a possible overheating boiler. Since I have to cut into the piping around the boiler I am going to try and solve this too.

The heated water travels from the boiler to the house 100' underground through 1&1/4" PEX.

I want to put a tee into the return line before it gets to the Laddomat. The return line is 1&1/4" and the new line coming off would be 3/4". On this line there would be a circulator (hooked up to a relay, battery and an inverter to power it during an outage) that would go into the boiler through a previously unused tapping.

I have attached a piss-poor diagram of my idea. The yellow box is what I would like to add to the current setup.

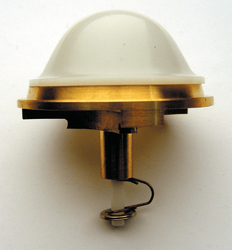

My plan was to use a Grundfos UPS15-58FC circulator to move the water. I want to move enough cool water into the boiler, by bypassing the Laddomat, as soon as the power cuts off.

Will this work for my situation?

The heated water travels from the boiler to the house 100' underground through 1&1/4" PEX.

I want to put a tee into the return line before it gets to the Laddomat. The return line is 1&1/4" and the new line coming off would be 3/4". On this line there would be a circulator (hooked up to a relay, battery and an inverter to power it during an outage) that would go into the boiler through a previously unused tapping.

I have attached a piss-poor diagram of my idea. The yellow box is what I would like to add to the current setup.

My plan was to use a Grundfos UPS15-58FC circulator to move the water. I want to move enough cool water into the boiler, by bypassing the Laddomat, as soon as the power cuts off.

Will this work for my situation?