Well I just drained it after running the pre-cleaner and am now filling it backup with the filtered water. I found that draining with just a hose on the boiler drain I put on the bottom of the tank took forever. I ended up buying a submersible pump and using that to finish the job, well worth the $100.

Garn is up and running

- Thread starter curtis

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

RowCropRenegade

Feeling the Heat

I hear you Reed, we have warmed up to -22 at present, it will take two full burns for 24 hours. I would much rather burn 300# of wood than the equivalent in LP. I had a trouble call at 2am, -27*, when a LP furnace didn't want to burn LP either.

I do burn a little LP in my vent less fireplace. It's so cheap to burn for supplement to the Garn. Like sunday night, -13 and wind 30 mph. Gan was fully charged at 205 mid nite. By 6 am, it said it was at 170 but actually supply in house was 140. Variable rate pump was 100% and tstat was 4 below setpoint of 65. Turned on fireplace, fired Garn. Within 1 hour, I was back to setpoint and Garn could deliver hot enough temperature to supply house. Maybe burned .2 gallons of LP. Quick catch up.

I'm envious of your ability to use low water temps. I turn a profit on the Garn project this year, so the next step is trying to tighten up this BTU black hole that is my house, lol!

I ended up buying a submersible pump and using that to finish the job, well worth the $100.

I added a second drain point to my system. At the point where my return lines come back into the Garn, I ran 2" black pipe back to the Garn return port, and with a tee fitting on that 2" line, and ran another small section of black pipe and fitted it with a brass straight valve that I can hook a hose up to. Of course, once the water drops below the return line, it doesn't do any good. However, for a while it gives you at least two drain ports to speed the process.

deerhntr

Member

Curtis,

Congrats to bringing the beast online. You can gain a great deal of operational knowledge by tapping into this forum.

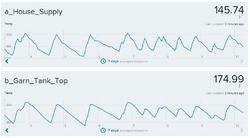

Just thought I would add a plot of my temps over the past week so you can see how we operate our garn. During the winter heating season, we normally burn once a day. But when the polar vortex invades PA, we stepped it up to twice. You can see from the plot below, on 1/4,1/5, and 1/6 we burnt once, and ran from ~200F down to ~150F per day. Then you can see on 1/7, 1/8, and 1/9 we burnt another small load in the morning to boost it up for the day while at work. We most likely would have been o.k. burning only once, I just wanted to be sure I didn't have to play catch-up when I got home from work.

Any way, good luck with your new system.

Congrats to bringing the beast online. You can gain a great deal of operational knowledge by tapping into this forum.

Just thought I would add a plot of my temps over the past week so you can see how we operate our garn. During the winter heating season, we normally burn once a day. But when the polar vortex invades PA, we stepped it up to twice. You can see from the plot below, on 1/4,1/5, and 1/6 we burnt once, and ran from ~200F down to ~150F per day. Then you can see on 1/7, 1/8, and 1/9 we burnt another small load in the morning to boost it up for the day while at work. We most likely would have been o.k. burning only once, I just wanted to be sure I didn't have to play catch-up when I got home from work.

Any way, good luck with your new system.

Sawyer

Minister of Fire

I'm curious Russ, what are the double spikes at peak temps on 1-3, 6, and 7? Did you add more wood at the end of the burn?

deerhntr

Member

George,I'm curious Russ, what are the double spikes at peak temps on 1-3, 6, and 7? Did you add more wood at the end of the burn?

Yes, that is exactly what was going on. The house supply sensor, in on the Heat Exchanger side of the pump, so that will show some spikes as the pump turns off and on. But the Tank sensor is in the well next to the Mechanical thermometer. That will always show a smooth plot. Looks like, do to the high demand for heat, and me being lazy, I let the burn drop almost out until I added wood again.

-Russ

Last edited:

Sawyer

Minister of Fire

Thanks Russ, glad to see that I am not the only one that does that. I am especially vulnerable when I am burning small branch wood and trying to avoid puffing by adding in less than capacity bunches.

I am especially vulnerable when I am burning small branch wood and trying to avoid puffing by adding in less than capacity bunches.

I am especially vulnerable when I am burning small branch wood and trying to avoid puffing by adding in less than capacity bunches.

I am especially vulnerable when I am burning small branch wood and trying to avoid puffing by adding in less than capacity bunches.Robert V

Member

I know it's off topic but I just happen to see wavy air coming out of the stack of my garn this weekend. The last burn was aprox 12 hours ago so this was hot air created by a draft through the unit not normal chimney heat from the fire. I know it is a vertical unit and they recommend a damper in the inlet but I want to keep my system simple. I was thinking about some type of flapper like you find on a semi. Do you think this would restrict my flow when running by forcing the the blower to push the door open? Any other ideas?

BHetrick10

Member

Are your guys going off the tank temp or the supply temp to make a fire. I went off my tank temp and over shot up to 211 and had some water come out. While this was going on my supply is 40* less.

My supply always seems to be a min of 25 but mostly 40 degrees lower than tank.

So that bring me to I have a 120 degree supply 160 tank and would have make a small fire and more often. If I let the tank get to 140 my supple is only 100. I really dont want the supply to go lower than 140. I will be running the primary loop through a plate exchanger for the DHW and then my secondary loops are 140 for is joist cavities and 110 in the concrete.

also I only have the garn shed insulated very. The garn only has R30 rolls of insulation on it tight together, draping over the sides.

My supply always seems to be a min of 25 but mostly 40 degrees lower than tank.

So that bring me to I have a 120 degree supply 160 tank and would have make a small fire and more often. If I let the tank get to 140 my supple is only 100. I really dont want the supply to go lower than 140. I will be running the primary loop through a plate exchanger for the DHW and then my secondary loops are 140 for is joist cavities and 110 in the concrete.

also I only have the garn shed insulated very. The garn only has R30 rolls of insulation on it tight together, draping over the sides.

Sawyer

Minister of Fire

Your temperature spreads seem similar to mine after the Garn has been setting for a while. On mine the supply temp and thermometer on the front to the Garn will read pretty similar at the end of a burn. I fire by the supply temperature. Did you calibrate your thermometers?

If I fill my Garn to the recommended level and fire to 200 degrees I will have water run out of the overflow. It would also if I fired again and ran it up to 210 as it would expand more this time. After the initial overflow, very little comes out of the overflow below 170 degrees on mine. Above 170 there are a few drops and a little vapor. I refill mine twice a year.

If I fill my Garn to the recommended level and fire to 200 degrees I will have water run out of the overflow. It would also if I fired again and ran it up to 210 as it would expand more this time. After the initial overflow, very little comes out of the overflow below 170 degrees on mine. Above 170 there are a few drops and a little vapor. I refill mine twice a year.

BHetrick10

Member

I am burning once every 24 hrs +/- a few depending on tank supply temp.

Didnt know sensors could be calibrated. I do not have a sensor in the front yet.

Tonight when i lit the fire supple was only 86 tank 130. ten min in egt was 422 supply was 113 tank 130.

Didnt know sensors could be calibrated. I do not have a sensor in the front yet.

Tonight when i lit the fire supple was only 86 tank 130. ten min in egt was 422 supply was 113 tank 130.

Sawyer

Minister of Fire

I would doubt you could calibrate the sensors and would not know how to do that if you can. I have the older style and use thermometers which can be calibrated.. My temps come together shortly after firing with the tank temperature dropping as the water mixes from the firing. Basically I ignore tank temperature. My flue temperature and supply temperature read almost identical before firing so I determine how much wood to burn based on the flue and don't even bother to go look at the supply temp anymore.

I would imagine sensor location would contribute to our temperature differences. Can you read your flue temperature before firing? Does that match your supply temp readout?

I would imagine sensor location would contribute to our temperature differences. Can you read your flue temperature before firing? Does that match your supply temp readout?

Rick Stanley

Feeling the Heat

I have the same difference between tank and supply temps. As you guys say, they are equal during a burn. I don't worry about that anymore. Also there has been concern about over-firing, when to burn, at what tank temp to burn etc. Also I got worried about stack temps for awhile. After a few seasons of tinkering with different plumbing set-ups, insulating etc, I finally got it so it will heat my house YAY. Of course I heat with different temperature water depending on the weather and naturally lower water temp is better. So, when the house gets cold I build a fire.

BHetrick10

Member

My egt will usually be lower than supply 10-20. I assume air is traveling through exchange tubes? I put a wad of insulation in end of exhaust after a burn to help keep that from happening.

So am I going to have to make small fires and more of them?

Anyone have trouble with there Controller? My gfci died during my third burn. On my 6th burn the fan never shut off. The timer said a little Over three hrs but when I checked it twelve hrs later the fan was running. It did a great job at cooling off my whole tank.

So am I going to have to make small fires and more of them?

Anyone have trouble with there Controller? My gfci died during my third burn. On my 6th burn the fan never shut off. The timer said a little Over three hrs but when I checked it twelve hrs later the fan was running. It did a great job at cooling off my whole tank.

just filled my boiler and the tank temp read 145 and the supply read 115. Im going to try firing it until the supply temp is in the 180-190 range this time. I have been firing till the tank temp was in that range. Maybe now i will be getting the whole tank up to the 180-190 range.

Gasifier

Minister of Fire

I loaded the boiler about 3/4 full with ash and after 54 minutes the supply went from 115 to 143. I did notice though that the flue is 545 degrees F. Is that too high? I've normally seen it around 450.

Sawyer

Minister of Fire

Dry ash, especially splits, can still be burning pretty hot after 54 minutest, 3/4 full would be about a 2 hour burn for mine. I wouldn't worry about your 545* reading, your unit is too new to worry about cleaning the flues as long as you are burning dry wood.

I agree with Rick, after a while you start ignoring the variables between different burns and just light a fire when you want higher heat levels in the Garn. I would go by your supply temperatures.

I agree with Rick, after a while you start ignoring the variables between different burns and just light a fire when you want higher heat levels in the Garn. I would go by your supply temperatures.

I went by my supply temp today. The supply was 183 and the tank was 198. I'm sure by doing it this way now my furnace blower won't run as long with the hotter water coming out of the garn now.

Well in the last 27 days I have used almost a cord of wood to heat the house with the garn. From what I have read the wood I'm using (white ash) has a btu content of 21.6 million per cord. So if the boiler is 80% efficient and I went 27 day on that much wood, that means I averaged roughly 27k btu an hour to heat my house. Is that right?

Also figured that it would have taken 125 gallons of heating oil or $500 to heat my house in last 27 days. So the $67.50 I spent on a cord of wood plus my time to cut and split it was defiantly worth it.

And when I say cord I do mean 128 cubic feet.

Also figured that it would have taken 125 gallons of heating oil or $500 to heat my house in last 27 days. So the $67.50 I spent on a cord of wood plus my time to cut and split it was defiantly worth it.

And when I say cord I do mean 128 cubic feet.

Robert V

Member

Well in the last 27 days I have used almost a cord of wood to heat the house with the garn. From what I have read the wood I'm using (white ash) has a btu content of 21.6 million per cord. So if the boiler is 80% efficient and I went 27 day on that much wood, that means I averaged roughly 27k btu an hour to heat my house. Is that right?

Also figured that it would have taken 125 gallons of heating oil or $500 to heat my house in last 27 days. So the $67.50 I spent on a cord of wood plus my time to cut and split it was defiantly worth it.

And when I say cord I do mean 128 cubic feet.

Where are you in MI? That's a good price per cord. They get around $1,000 for a 10 cord semi load of oak around here.

Where are you in MI? That's a good price per cord. They get around $1,000 for a 10 cord semi load of oak around here.

I am in Boyne City, I know a logger so I get a little bit of a deal but ya I pay $1350 for a 20 cord load. I think the "regular" price most pay around me is 70-75 a cord.

eauzonedan

Member

It's running about $80 a chord for a 12 cord load of red/white oak dropped +/- 20 miles no of Hayward wi. I saw some new rules on max transport distance and holding times of only weeks may be coming for mn due to gypsy moth. Between that and the lp mess it may be going up......ish!

heaterman

Minister of Fire

My son Matt just got a 10 cord load of mixed hardwood, mostly oak, from Bisballe Forest Products for $750 dropped in his yard. They are just a bit north of us here. I think they deliver all over this part of the state and most of their wood has been yarded for at least a year if not two. If anyone would like their phone number shoot me a PM.

maple1

Minister of Fire

Jeebers - I might have to give up my scrounging time if I could buy wood that cheap around here.

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 5

- Views

- 415

- Replies

- 0

- Views

- 442

- Replies

- 16

- Views

- 2K